What is Supply Chain Management (SCM)?

Supply chain management (SCM) is the management of the entire production flow of a good or service — all the way from materials to production to distribution. It is a cross-functional approach, integrating activities into supply-chain processes.

Supply chain management (SCM) is the management of the entire production flow of a good or service — all the way from materials to production to distribution. It is a cross-functional approach, integrating activities into supply-chain processes.

Put simply, SCM is the handling of all supply chain activities, starting with sourcing raw components, creating the product, delivering the final product to consumers and then reverse logistics. An SCM manager is tasked with ensuring that all key supply chain processes are as optimized as possible.

The goal is to maximize efficiency and customer value. Companies that properly manage their supply chain can cut excess costs and get the products they make delivered to consumers faster.

The term “supply chain management” was first introduced by Keith Oliver, a consultant at Booz Allen Hamilton, during an interview for the Financial Times in 1982.

The Association for Supply Chain Management defines supply chain management as the “design, planning, execution, control, and monitoring of supply-chain activities with the objective of creating net value, building a competitive infrastructure, leveraging worldwide logistics, synchronizing supply with demand and measuring performance globally.”

NC State University says the concept of SCM is based on the following two ideas:

- All products that reach an end user represents “the cumulative effort of multiple organizations”. These organizations are collectively known as the supply chain.

- Even though supply chains have existed for a while, a lot of organizations only focused on what was going on within their “four walls.” Not many businesses understood, or managed, the entire chain of activities that delivered products to the final consumer. “The result was disjointed and often ineffective supply chains.”

Why is SCM important?

According to an article by Atul Borade and Satish V. Bansod published the Journal of Technology Management and Innovation, “The management of the supply chain and the roles of various actors involved differ from industry to industry and company to company. As a result Supply Chain Management (SCM) has become a vital issue for manufacturers, professionals and researchers. It is felt that to manage the supply chain effectively entire structure of supply chain must be understood properly.”

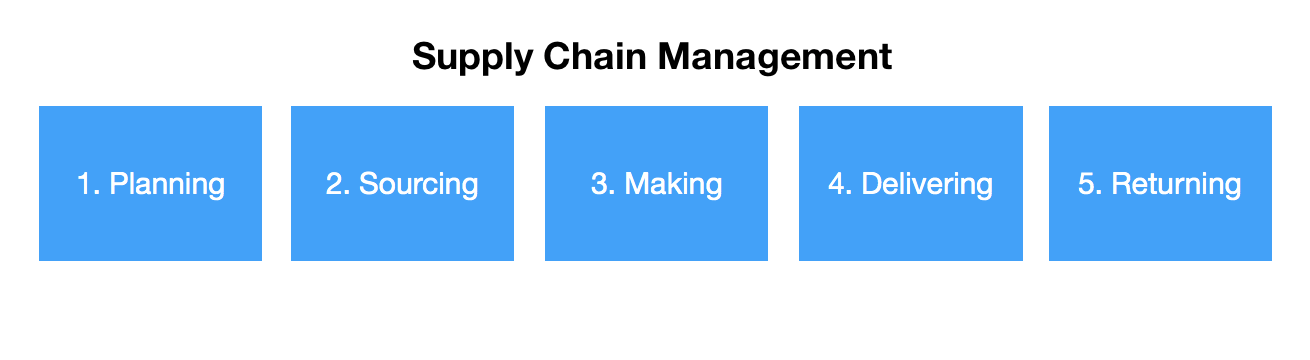

The main components of SCM

- Planning – making a strategy, planning the process.

- Sourcing – sourcing the raw materials or services needed.

- Making – manufacturing the product.

- Delivering – the flow of things from manufacturing the product to the point of consumption to meet requirements of customers or corporations. The logistics of shipping and delivering the product.

- Returning – devising a system of returns and exchanges (reverse logistics).

Seven principles of SCM

According to smartsheet, there are seven principles of SCM:

- Adapt supply chain based on needs of each segment.

- Customize logistics based on needs of each segment.

- Align demand planning across supply chain.

- Outsource strategically

- Differentiate product closer to consumer.

- Develop information technology that support multi-level decision making.

- Adopt service and financial metrics.

Handling people in the supply chain

One of the hardest things about SCM is the management and handling of individuals in the supply chain and ensuring that they are all motivated and happy working together. To help ensure that relationships are good managers should focus on: leadership style, management style, company culture, product flows, information flows and rewards and risks.

Video explanation

The video embedded below, by W. P. Carey School of Business, provides a visual explanation of supply chain management. The video describes the complex supply chain of a simple product, a bottle of water.