A team of scientists has found a low-cost method of producing graphene printed electronics. The method speeds up and reduces the cost of conductive graphene inks considerably.

The researchers, based at the University of Manchester, wrote about their work in Nature Communications (citation below).

Printed electronics is a set of printing methods we can use to create electrical devices on a variety of substrates. It offers a breakthrough in the penetration of IT into everyday life. IT stands for information technology.

Printed electronics has the potential to promote the spread of IoT further. IoT (Internet of things) is a system of interrelated objects, machines, devices, people, and even animals that communicate with each other.

Printed electronics – conductive inks

There has been a rapid development of printed conductive inks or electronic applications. This has widened the number of applications in wearable electronics, RFID tags, and sensors. It has also widened applications in sensors and transistors.

Current conductive inks have traditionally been good conductors of electricity because of the metal nanoparticles placed in them. However, metal nanoparticles oxidize easily and can also be expensive. Therefore, they are not ideal for low cost IoT applications.

The team has found that using Cyrene (dihydrolevogucosenone) is not only environmentally-friendly but non-toxic and sustainable. It can also provide greater concentrations and conductivity of graphene ink.

Prof Zhirun Hu, Reader, Deputy Head of Materials, Devices and Systems Division and School Output Champion, said:

“This work demonstrates that printed graphene technology can be low cost, sustainable, and environmentally friendly for ubiquitous wireless connectivity in IoT era as well as provide RF energy harvesting for low power electronics.”

Graphene moving rapidly into application domain

Professor Sir Kostya Novoselov, FRS, best known for isolating graphene in 2004 at the University of Manchester, said:

“Graphene is swiftly moving from research to application domain. Development of production methods relevant to the end-user in terms of their flexibility, cost and compatibility with existing technologies are extremely important. This work will ensure that implementation of graphene into day-to-day products and technologies will be even faster.”

Lead author, Kewen Pan, a Research Associate, said:

“This perhaps is a significant step towards commercialization of printed graphene technology. I believe it would be an evolution in printed electronics industry because the material is such low cost, stable and environmentally friendly.”

What is graphene?

Graphene, which is just one atom thick, is the first truly two-dimensional material we know of. It is amazingly light yet super tough. Graphene is two hundred times stronger than the world’s strongest steel.

It is also a superb conductor of electricity and heat and acts as the perfect barrier.

Not only is graphene super hard but it is also amazingly flexible. This is a rare feature for tough and hard materials.

Graphene has potential applications in contrast agents, bioimaging, tissue engineering, electronic devices, and drug delivery. In fact there are hundreds of possible applications. At the University, apart from printed electronics, researchers are looking into many other potential uses.

Citation

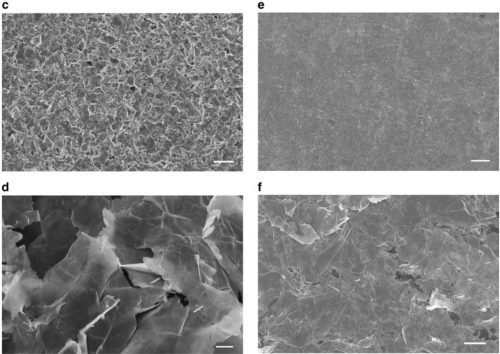

“Sustainable production of highly conductive multilayer graphene ink for wireless connectivity and IoT applications,” Kewen Pan, Yangyang Fan, Ting Leng, Jiashen Li, Zhiying Xin, Jiawei Zhang, Ling Hao, John Gallop, Kostya S. Novoselov & Zhirun Hu. Nature Communicationsvolume 9, Article number: 5197 (2018). DOI: https://doi.org/10.1038/s41467-018-07632-w.