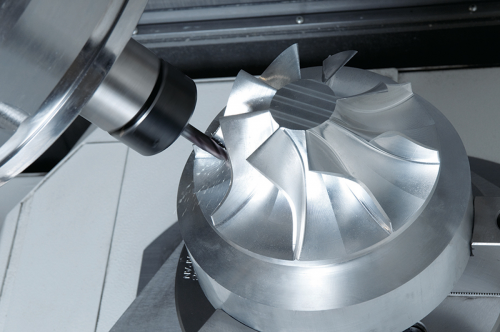

Machining has gained a lot of prominence, which is especially the case since more and more industries are becoming accustomed to the idea of mass precision manufacturing, which can be done by a CNC machine shop. CNC machining is already a very advanced process, but it is still improving on a consistent basis. Because of this, methods that can be performed by CNC services are becoming more precise, while a wider range of materials can be used as well. Because of this, experts expect that machine tools, which include CNC machines, will grow a lot when it comes to revenues.

Internet of Things in 2021

That CNC machining has gained so much prominence over the last few years, is also an effect of the Internet of Things. In the future, the IoT will expand and improve even more, which will propel CNC machining toward more widespread utility, while it will lead to greater revenues as well. The Internet of Things also stands to revolutionize a lot of manufacturing processes as it further digitizes and connects factories all over the world, including the CNC machine shops. However, some potential benefits really stand out as potential drivers of CNC machining growth, which will be affected by the IoT. These are mentioned below.

Preventative maintenance

Preventative maintenance is one of the main benefits of the IoT in manufacturing. It certainly is a factor when it comes to CNC machining as well. The Internet of Things actually allows for real-time and remote condition monitoring. This is the case for the products, but also for the machines themselves. Usually CNC machines are left alone to produce orders, but IoT connected sensors can ensure that they are doing this in an adequate way. On top of that, it can alert workers to any problems and can also give employees information about general maintenance of the CNC machines.

Big topic: Automated labor

Automated labor could make for a big topic of conversation unto itself, but it is still important to mention that the Internet of Things stands to enable other robotic systems to work together with CNC machining. You for example have to consider something as easy as organizing products once they have been created by the CNC machines. At the moment, this is usually a task performed by a person, but with the IoT this will no longer have to be the case in the future. Instead this process can be fully automated.

Product quality control of CNC machining

When the IoT works in conjunction with CNC machining efforts, companies can outfit all created parts with a tiny sensor. This is connected to a larger network. By doing this, you make it easier to track the products throughout the assembly and shipping process. On top of that, the sensors also simplify recognizing and addressing production errors. These do not occur often when using CNC machines, but failures can still happen of course. If a sensor detects a defect, the CNC machining process can then be halted so the issue can be sorted out.

Interesting Related Article: “CNC machining or 3D printing, what is the best way to make your part? “