The sticky coating that exists in a spider’s web has amazing properties capable of creating a liquid wire that can be stretched several times its length, but still remains taught, says a team of British and French scientists.

Have you ever wondered why a spider’s web never sags in the wind, or why a catapult flies back out like a trampoline? According to researchers from the University of Oxford in England and the Université Pierre et Marie Curie in Paris, France, the answer lies in the physics behind a ‘hybrid’ material that spiders produce for their webs.

If you pull on a sticky thread of a spider’s orb web and let it snap back, you will notice that the threat always stays taught – it will never sags – even if you stretch it to several times its original length.

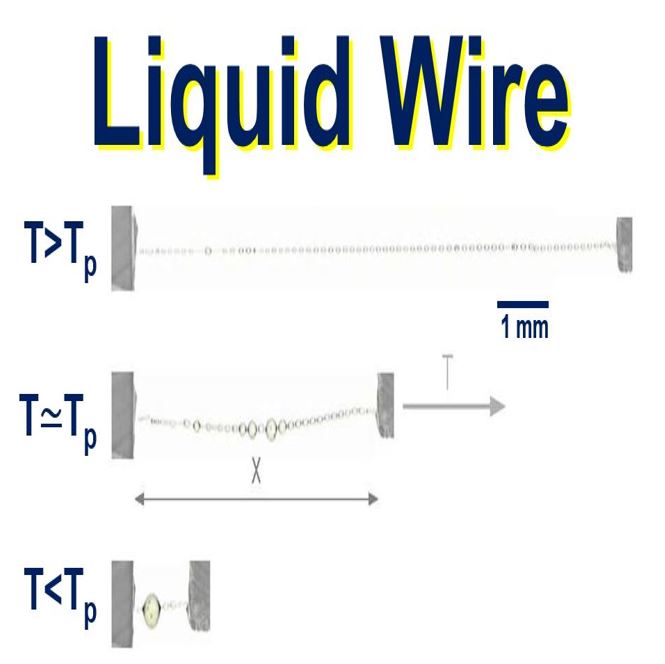

A liquid wire. Whether relaxed or stretched, the typical silk thread of a spider remains taut. ‘T’ = tension. (Image: PNAS)

A liquid wire. Whether relaxed or stretched, the typical silk thread of a spider remains taut. ‘T’ = tension. (Image: PNAS)

Spider web’s thread always remains taut

It does this because any loose thread is spooled inside minuscule droplets of watery glue that coat the core gossamer fibres of the spider web’s capture spiral.

Professor Fritz Vollrath, who works at the Oxford Silk Group in the Department of Zoology at Oxford University, and colleagues wrote about this phenomenon in the journal PNAS (citation below).

The scientists studied the details of this ‘liquid wire’ technique in webs and used it to create composite fibres in the lab which extend like a solid and compress like a liquid, just like a spider’s capture silk.

The authors believe that these novel insights could lead to new bio-inspired technology.

Why doesn’t a spider’s web sag when it is windy? The threads in the web are covered in tiny glue droplets that, apart from entrapping insects, also have mechanical properties – each droplet spools and packs the core silk filament, thus keeping the thread and the whole web under tension. (Image: University of Oxford)

Why doesn’t a spider’s web sag when it is windy? The threads in the web are covered in tiny glue droplets that, apart from entrapping insects, also have mechanical properties – each droplet spools and packs the core silk filament, thus keeping the thread and the whole web under tension. (Image: University of Oxford)

Droplets reel in loose bits of thread

Prof. Vollrath said:

“The thousands of tiny droplets of glue that cover the capture spiral of the spider’s orb web do much more than make the silk sticky and catch the fly. Surprisingly, each drop packs enough punch in its watery skins to reel in loose bits of thread.”

“And this winching behaviour is used to excellent effect to keep the threads tight at all times, as we can all observe and test in the webs in our gardens.”

The new properties that the scientists observed and analysed rely on a subtle balance between droplet surface tension and fibre elasticity.

The researchers were also able to recreate this technique in the lab using oil droplets on a plastic filament. This artificial system behaved exactly like the spider’s natural winch silk, which spools the filament reeling and unreeling inside the tiny oil droplets as the threat extends and then contracts.

#SpiderSilk Inspires Creation of #LiquidWire https://t.co/oLZ4iFnCAK #prettycool pic.twitter.com/C3eubScQJw

— MichaelLoBurgio (@MikeLoBurgio) 17 May 2016

First author, Dr Hervé Elettro, a doctoral researcher at Institut Jean Le Rond D’Alembert, Université Pierre et Marie Curie in Paris, said:

“Spider silk has been known to be an extraordinary material for around 40 years, but it continues to amaze us. While the web is simply a high-tech trap from the spider’s point of view, its properties have a huge amount to offer the worlds of materials, engineering and medicine.”

“Our bio-inspired hybrid threads could be manufactured from virtually any components. These new insights could lead to a wide range of applications, such as microfabrication of complex structures, reversible micro-motors, or self-tensioned stretchable systems.”

In an Abstract in the journal, the authors wrote:

“Each of the droplets can spool and pack the core silk filament, thus keeping the thread and the whole web under tension. We demonstrate that this effect is the result of the interplay between elasticity and capillarity by making a fully artificial drops-on-fiber compound as extensible as capture thread is.”

Citation: “In-drop capillary spooling of spider capture thread inspires hybrid fibers with mixed solid–liquid mechanical properties,” Hervé Elettro, Sébastien Neukirch, Fritz Vollrath, and Arnaud Antkowiak. PNAS (Proceedings of the National Academy of Sciences). May 16 2016. DOI: 10.1073/pnas.1602451113.

Video – Synthetic spider sik coils within oil droplet

In this University of Oxford video, you can see a thread coiling within a tiny droplet of oil.