Scientists have demonstrated how it is possible to make large-scale graphene. One of the biggest problems with graphene, the world’s strongest, lightest and thinnest material, is making it big enough for it to have any serious potential. Researchers so far have been limited to using small flakes.

Scientists at the Department of Energy’s Oak Ridge National Laboratory (ORNL) say this small-scale barrier could be overcome using chemical vapour deposition – a chemical process for depositing thin films of various materials.

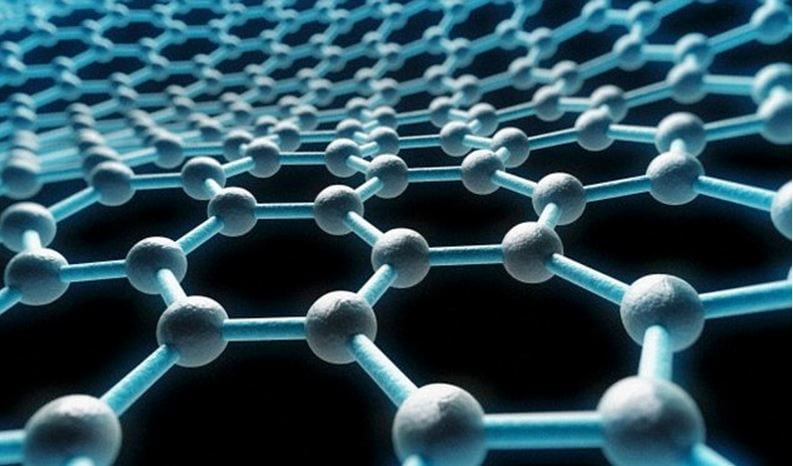

A research team led by Ivan Vlassiouk, who works at ORNL’s Energy and Transportation Science Division, has fabricated polymer composites containing 2-by-2-inch sheets of graphene, which consists of hexagonally arranged carbon atoms just one-atom thick.

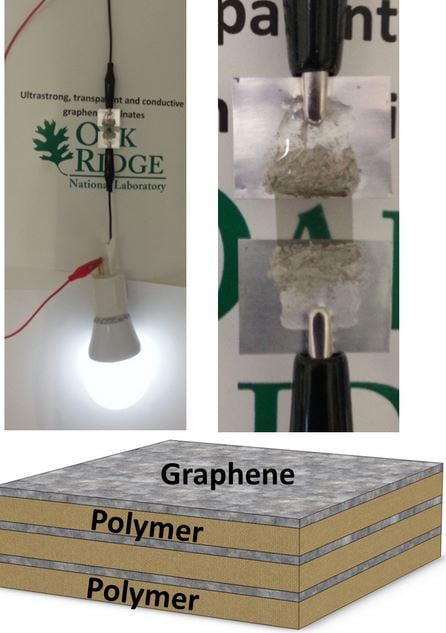

ORNL’s super-strong material features layers of graphene and polymers. It is an effective conductor of electricity. (Image: ornl.gov)

Graphene, a material 100 times stronger than steel, even stronger and stiffer than carbon fiber, has vast commercial potential, that is, if it can be made large enough.

Taking flexible electronics to a new level

Vlassiouk and colleagues wrote about their findings in the academic journal Applied Materials & Interfaces (citation below). They say their achievement could take flexible electronics to a new level and change how this reinforcing material is viewed and ultimately utilized.

Vlassiouk said:

“Before our work, superb mechanical properties of graphene were shown at a micro scale. We have extended this to a larger scale, which considerably extends the potential applications and market for graphene.”

While the majority of approaches for polymer nano-composition construction use minuscule flakes of graphene, or some other carbon nano-material, that are difficult to disperse in the *polymer, Vlassiouk and colleagues used comparatively huge sheets of graphene.

*Polymers consist of many, many molecules all strung together to form very long chains.

Using large-scale graphene eliminates flake dispersion and agglomeration problems, and allows it to conduct electricity better with less actual graphene in the polymer.

Vlassiouk said:

“In our case, we were able to use chemical vapor deposition to make a nano-composite laminate that is electrically conductive with graphene loading that is 50 times less compared to current state-of-the-art samples.”

This is a key to making graphene competitive on the market, the authors explained.

Graphene consists of a single layer of pure carbons laid out in a hexagonal lattice pattern.

Graphene has potential in several industries

If Vlassiouk and colleagues can lower the cost and demonstrate scalability (increase production rapidly while keeping down costs), they believe graphene could be used in several industries, including:

– Manufacturing: filtration, barrier coatings and catalysts.

– Energy: storage of energy, photovoltaics, and filtration.

– Aerospace: flame-retardants, conductive, anti-icing, and structural monitoring.

– Automotive: wear-resistant coatings and catalysts.

– Electronics: thermal management, printed electronics, and displays.

– Structural applications: temperature control materials and self-cleaning coatings.

Earlier this month, a team from the University of Trento in Italy sprayed spiders with graphene, which created webs strong enough to catch falling airplanes. Spider’s silk is the strongest natural substance on Earth.

By manipulating wrinkles, scientists in Japan believe graphene could be used to make semiconductors.

Citation: “Strong and Electrically Conductive Graphene-Based Composite Fibers and Laminates,” Ivan Vlassiouk, Georgios Polizos, Ryan Cooper, Ilia Ivanov, Jong Kahk Keum, Felix Paulauskas, Panos Datskos and Sergei Smirnov. Applied Materials & Interfaces. Published 28 April, 2018. DOI: 10.1021/acsami.5b01367.