A manned moon base by 2030 is being planned by the European Space Agency (ESA), the aim being explore the solar system, the Universe, and also discover alien life. The ‘Moon Village’ will be constructed utilizing 3D printers using materials that exist naturally on the Moon, say ESA scientists.

During a two day conference – ‘International Symposium on Moon 2020-2030’ – which was held at the Space Research and Technology Centre of the European Space Agency (ESA/ESTEC), 35km south-west of Amsterdam International Airport in The Netherlands, scientists said robots would land on the Moon first and prepare the surface for humans, who would arrive later.

During their presentations, they showed what the Moon base would look like and how the human pioneers would live.

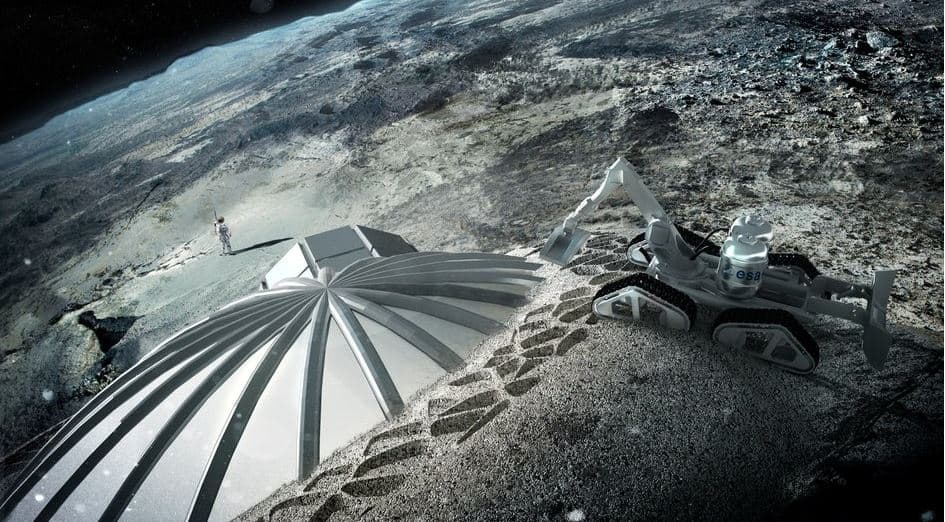

The multi-dome lunar base being constructed, based on the 3D printing concept. Once assembled, the inflated domes will be covered with a layer of 3D-printed lunar regolith by robots to help protect the inhabitants against space radiation and micrometeoroids (Image: www.esa.int. Credits: ESA/Foster + Partners)

The multi-dome lunar base being constructed, based on the 3D printing concept. Once assembled, the inflated domes will be covered with a layer of 3D-printed lunar regolith by robots to help protect the inhabitants against space radiation and micrometeoroids (Image: www.esa.int. Credits: ESA/Foster + Partners)

The Moon could then be used by astronauts as a base from which to blast off and explore planets and other celestial bodies in space, including Mars.

The moon is one-quarter the size of Earth, so its gravity is much less than the earth’s – 83.3% less to be exact. Launching rockets into space from the Moon is much easier and cheaper than from the Earth.

Ever since NASA found water on Mars, speculation about alien life out there has mushroomed.

Taking space exploration to the next level

The aim of the conference was to get the 200 scientists and experts who attended to talk about and plan humankind’s next giant leap into outer space.

Kathy Laurini, an engineer with more than 30 years of experience in NASA’s human spaceflight programs, who is a leader in NASA’s effort to enable human exploration into the solar system, believes that the European Moon base could serve as a stepping stone for astronauts travelling to Mars.

Building a future Moon base could be made much simpler utilizing a 3D printer using local materials. The base will first be unfolded from a tubular model that could be easily transported by space rocket. The inflatable dome would then extend from one end of a cylinder to provide a support structure for construction. (Image: ESA/Foster + Partners)

Building a future Moon base could be made much simpler utilizing a 3D printer using local materials. The base will first be unfolded from a tubular model that could be easily transported by space rocket. The inflatable dome would then extend from one end of a cylinder to provide a support structure for construction. (Image: ESA/Foster + Partners)

“The ESA space-exploration strategy sets the Moon as a priority destination for humans on the way to Mars. And the recent talk of a Moon Village certainly has generated a lot of positive energy in Europe – (of) Europe playing a role in a global human exploration scenario.”

“The timing is right to get started on the capabilities which allow Europe to meet its exploration objectives and ensure it remains a strong partner as humans begin to explore the solar system.”

Building moon base with 3D printers

According to ESA, it tested the practicability of using Moon soil with 3D printers in 2013, and created a material which could be used for building domes that would protect humans from the harmful effects of background space radiation as well as micrometeoroids.

Project Chief, Laurent Pambaguian, an expert on the metallic materials and processes employed to build space missions, who works at ESA’s Materials Technology section, said:

“Terrestrial 3D printing technology has produced entire structures. Our industrial team investigated if it could similarly be employed to build a lunar habitat.”

Robots will be sent to the Moon first, and will prepare the surface for humans. (Image: ESA/Foster + Partners)

Robots will be sent to the Moon first, and will prepare the surface for humans. (Image: ESA/Foster + Partners)

Scott Hovland of ESA’s human spaceflight team, said:

“3D printing offers a potential means of facilitating lunar settlement with reduced logistics from Earth. The new possibilities this work opens up can then be considered by international space agencies as part of the current development of a common exploration strategy.”

Xavier De Kestelier of Foster + Partners Specialist Modelling Group, remarked:

“As a practice, we are used to designing for extreme climates on Earth and exploiting the environmental benefits of using local, sustainable materials. Our lunar habitation follows a similar logic.”

This 1.5 tonne building block was created as a demonstration of 3D printing techniques using lunar soil. The design is based on a hollow closed-cell structure – like bird bones – to give a good combination of both weight and strength. (Image: www.esa.int)

This 1.5 tonne building block was created as a demonstration of 3D printing techniques using lunar soil. The design is based on a hollow closed-cell structure – like bird bones – to give a good combination of both weight and strength. (Image: www.esa.int)

Scientists across the world are becoming increasingly optimistic about finding both exoplanets capable of hosting life as we know it, and alien life itself.

The scientists used the British-made Monolite D-Shape printer, which has a mobile printing array of nozzles and a 6-metre frame to spray a binding solution onto sand-like building material.

3D ‘printouts’ are created layer by layer. Monolite UK Ltd. generally uses its printer to create sculptures, and is currently working on artificial coral reefs to help preserve beaches from sea waves.

Enrico Dini, founder of Monolite, explained:

“First, we needed to mix the simulated lunar material with magnesium oxide. This turns it into ‘paper’ we can print with. Then for our structural ‘ink’ we apply a binding salt which converts material to a stone-like solid.”

“Our current printer builds at a rate of around 2 m per hour, while our next-generation design should attain 3.5 m per hour, completing an entire building in a week.”

ESA Video – 3D printing a Moon base

In 2013, the European Space Agency, working with industrial partners, proved that 3D printing using material from the Moon was feasible in principle. Since then, work has continued to investigate the technique.