A composite metal foam has been created that literally turns a bullet into dust, including the most powerful armour-piercing bullets, a group of researchers from North Carolina State University report. This foam is much lighter than metal plating and has great potential for use in the creation of new types of vehicle and body armour, as well as space exploration and the transportation of nuclear waste.

Afsaneh Rabie, a professor of Mechanical and Aerospace Engineering, has spent several years developing composite metal foams (CMFs).

In a video published in YouTube (bottom of page), a composite armour made out of Prof. Rabiei’s composite metal foams is used.

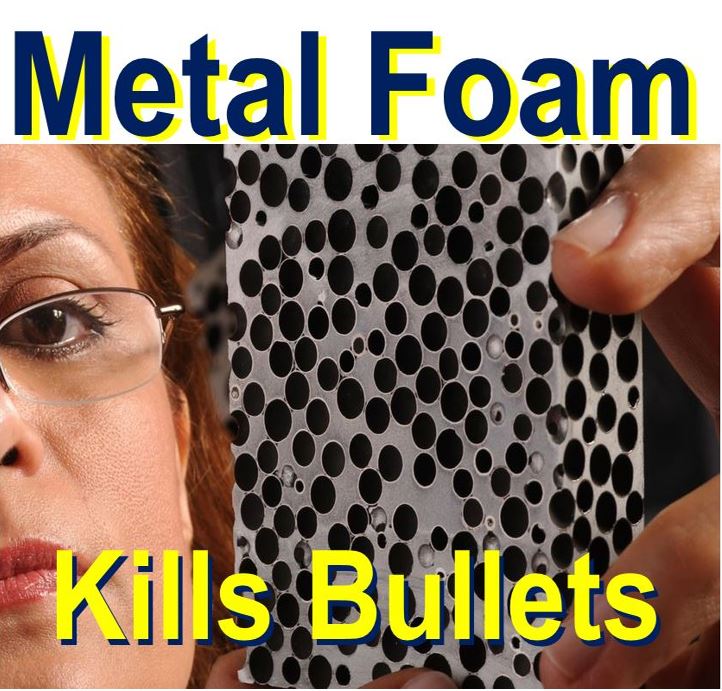

Professor Rabiei examines a sample of composite metal foam. This amazing material obliterates all types of bullets, and is a super shield from heat and radiation. (Image: news.ncsu.edu)

Professor Rabiei examines a sample of composite metal foam. This amazing material obliterates all types of bullets, and is a super shield from heat and radiation. (Image: news.ncsu.edu)

What is Composite Metal Foam?

Composite metal foams are formed from hollow beads of one metal within a solid matrix of another. The have been shown to have five to six time greater strength-to-density ratios and more than 7 times higher energy absorption than single metal foams.

“Composite Metal Foam is a new ultra-light, high-strength material developed in our group in order to address the increasing needs of the aerospace, military, naval, automotive, medical and other industries for advanced materials with outstanding strength to density ratio and energy absorption capability.”

Amazing results with powerful bullet

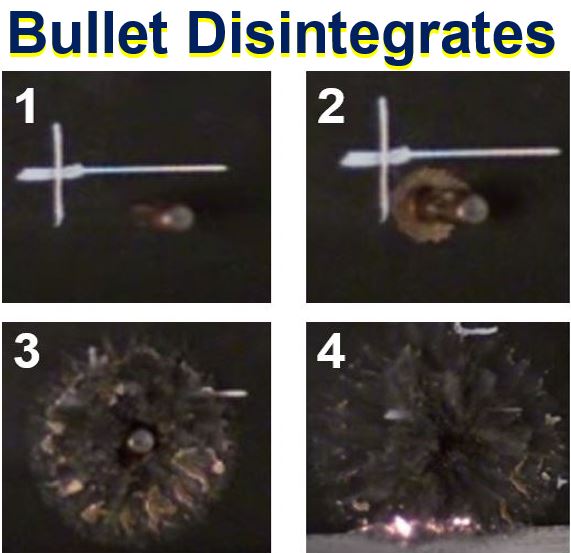

A powerful bullet – a 7.62 x 63 millimeter M2 armor piercing projectile – was used in the video demonstration. It was fired according to National Institute of Justice testing procedures. The results were astounding.

Prof. Rabiei said:

“We could stop the bullet at a total thickness of less than an inch, while the indentation on the back was less than 8 millimeters.”

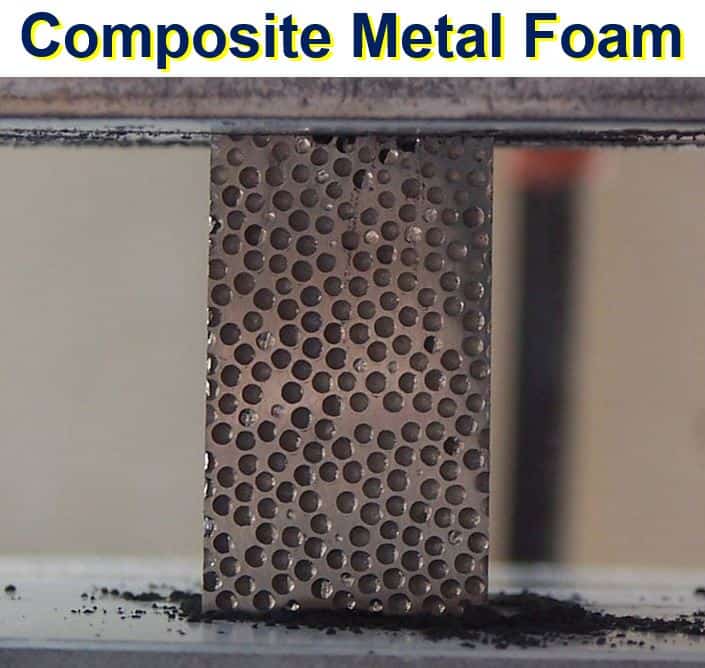

This composite metal foam will probably completely revolutionise several industries, especially those making materials for body/vehicle armour, space exploration, and the shipping of nuclear waste. (Image: news.ncsu.edu)

This composite metal foam will probably completely revolutionise several industries, especially those making materials for body/vehicle armour, space exploration, and the shipping of nuclear waste. (Image: news.ncsu.edu)

“To put that in context, the NIJ standard allows up to 44 millimeters indentation in the back of an armor.” The results of that study were published in the journal Composite Structures in July 2015.

There are several different applications, the researchers explain, that require a material to be more than just ultra-strong and super-light.

For example, applications from shipping nuclear waste to space exploration require a material to be both light and strong, and also capable of withstanding very high temperatures and blocking radiation.

Foam also shields from radiation

In 2015, with support from the Department of Energy’s Office of Nuclear Energy, Prof. Rabiei showed that composite metal foams are extremely effective at shielding X-rays, neutron radiation and gamma rays.

Last month, Prof. Rabiei published work demonstrating that the team’s metal foams handle fire and heat twice as effectively as the plain metals they are made of.

When the high-powered amour-piercing bullet touches the metal foam, it literally disappears in a puff of dust. (Images: YouTube)

When the high-powered amour-piercing bullet touches the metal foam, it literally disappears in a puff of dust. (Images: YouTube)

Now that these composite metals foams are becoming better understood, there could be a vast range of technologies that make use of this incredible tough and light material. The researchers wrote: “Armor, if you’ll forgive the pun, barely scratches the surface.”

Prof. Rabiei said:

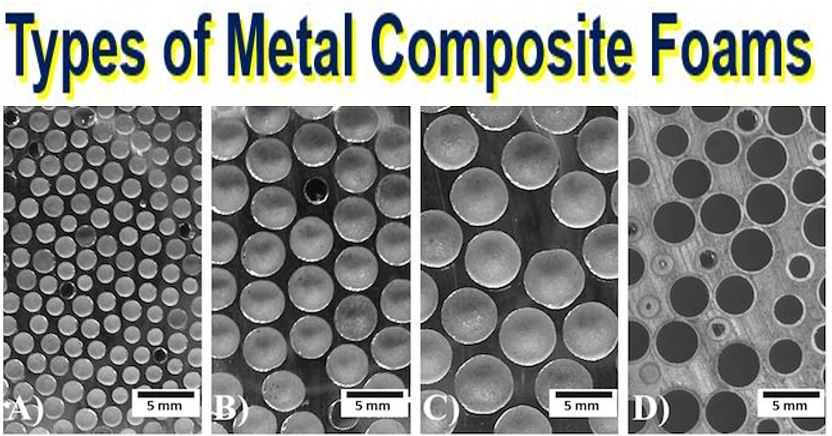

“The presence of air pockets inside CMF make it so effective at blocking heat, mainly because heat travels more slowly through air than through metal. The composite metal foam consists of metallic hollow spheres – made of materials such as carbon steel, stainless steel or titanium – embedded in a metallic matrix made of steel, aluminum or metallic alloys.”

There are many different types of composite metals foams. (Image: mae.ncsu.edu)

There are many different types of composite metals foams. (Image: mae.ncsu.edu)

“We have developed two technologies for manufacturing CMFs. One is based on casting a low melting point matrix material, such as aluminum, around hollow spheres made of a material with a higher melting point, such as steel. This creates aluminum-steel CMFs, for example.”

“The other technique is based on sintering, or baking, the matrix powder around prefabricated hollow spheres. This creates CMFs such as steel-steel, which consist of steel hollow spheres in a steel matrix.”

NCState Video – Metal foam obliterates bullets

Composite metal foams are super tough. Tough enough to turn an armor-piercing bullet into dust on contact. Given that these foams are also lighter than metal plate, the material has obvious implications for creating new types of body and vehicle armor.