Scientists in Germany have developed a way to produce protein and vitamin B9 using microbes that feed on a combination of hydrogen, oxygen, and CO2. This innovation, published on September 12 in the journal Trends in Biotechnology (citation below), uses renewable energy to create a sustainable alternative to traditional protein sources that could one day be used in our diets.

Prof. Dr. Ir. Largus (Lars) T. Angenent, from the Faculty of Mathematics and Natural Sciences at Eberhard Karls University of Tübingen in Germany, explained:

“This process is similar to brewing beer, but instead of feeding the microbes sugar, we provide them with gas and acetate. We already knew yeast could produce vitamin B9 with sugar, but we weren’t sure if it could also do this with acetate.”

Creating Protein in Bioreactors

Angenent emphasizes that with a global population nearing 10 billion and environmental pressures like climate change and limited land, producing enough food will become increasingly difficult.

One solution is to create protein in bioreactors through biotechnology, which is much more efficient than traditional farming.

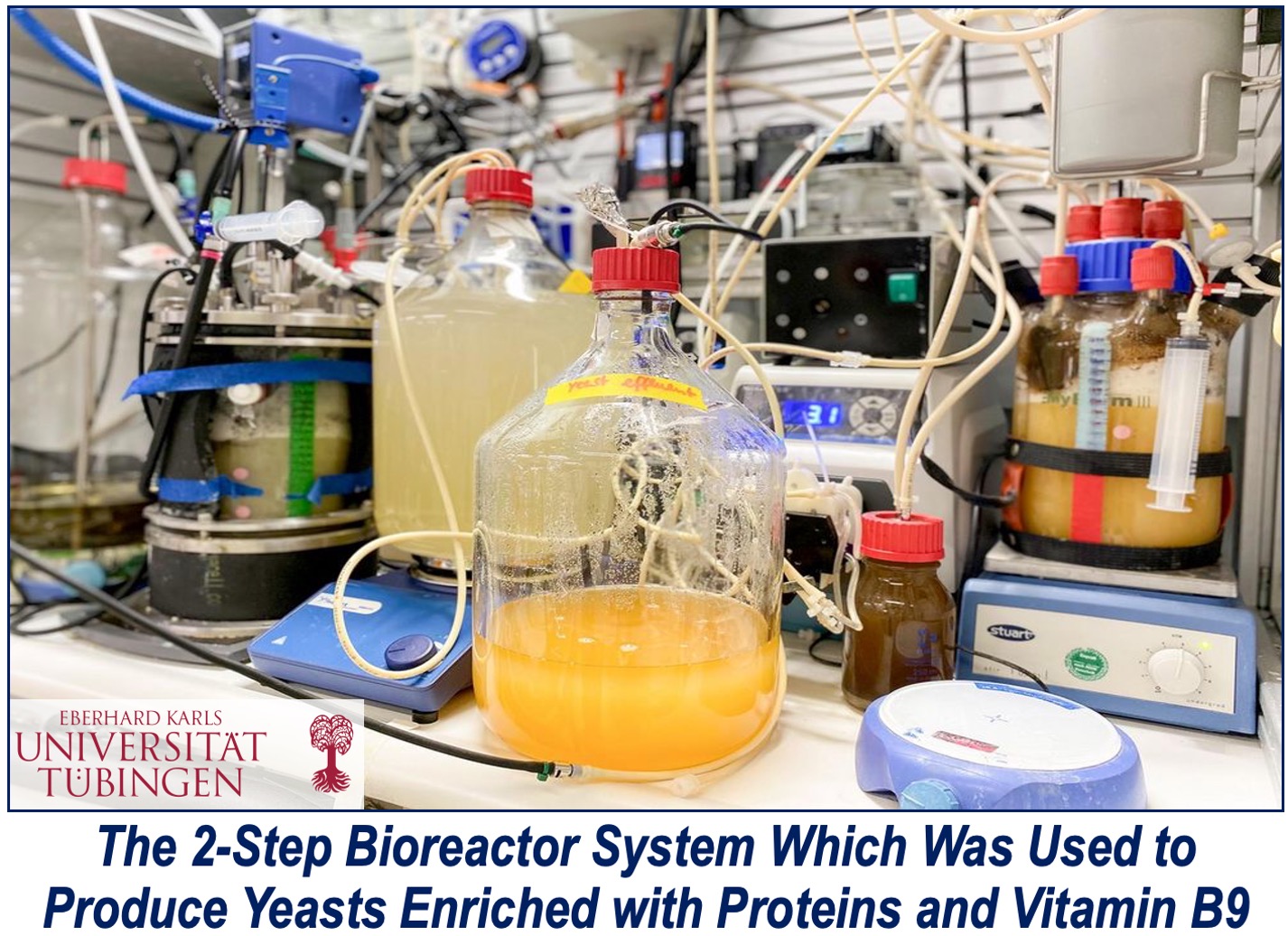

The research team designed a bioreactor system that works in two stages.

- First, the bacterium Thermoanaerobacter kivui transforms hydrogen and CO2 into acetate, a compound found in vinegar.

- In the next stage, the yeast Saccharomyces cerevisiae, commonly known as baker’s yeast, uses the acetate and oxygen to produce protein and vitamin B9. The hydrogen and oxygen are generated by splitting water using renewable energy sources like wind power.

Interestingly, yeast fed with acetate produces about the same amount of vitamin B9 as yeast fed with sugar. According to the study, just 6 grams (0.4 tablespoons) of dried yeast provides the daily recommended intake of vitamin B9. This was confirmed by Michael Rychlik’s team at the Technical University of Munich.

More Protein than Meat, Fish, or Lentils

When it comes to protein, the yeast developed in this process contains more protein than beef, pork, fish, or lentils.

For example, 85 grams (6 tablespoons) of yeast provides 61% of the daily protein requirement, compared to 34% from beef, 25% from pork, and 38% from lentils. However, the yeast needs to be treated to remove compounds that could increase the risk of gout if consumed in large quantities.

Even after treatment, the yeast still supplies 41% of daily protein needs, comparable to traditional sources.

Environmentally Friendly and Boosts Food Security

This technology offers solutions to global challenges such as environmental sustainability, food security, and public health. It minimizes carbon emissions in food production and frees up land for conservation by eliminating the need for farming space.

Angenent notes that the technology won’t compete with farmers but will allow them to focus on sustainable crop production. The yeast could also provide essential nutrients to developing countries.

Despite the promising results, Angenent says there is still work to be done before this yeast can become a common protein alternative. The team plans to improve the process, ensure food safety, and explore its economic viability.

Angenent concluded:

“The fact that we can produce both vitamins and protein efficiently without using land is really exciting. It’s a vegetarian, non-GMO, and sustainable option that could appeal to many consumers.”

Citation

Schmitz, L. M., Kreitli, N., Obermaier, L., Weber, N., Rychlik, M., & Angenent, L. T. (2024). Power-to-vitamins: Producing folate (vitamin B9) from renewable electric power and CO2 with a microbial protein system. Trends in Biotechnology. https://doi.org/10.1016/j.tibtech.2024.09.002