South Korean researchers have developed an OLED panel which uses graphene for its transparent electrodes.

South Korea’s Electronics and Telecommunications Research in cooperation with Hanwha Techwin used graphene to replace indium tin oxide, known as ITO, the conventional material used to make transparent electrodes in OLED panels.

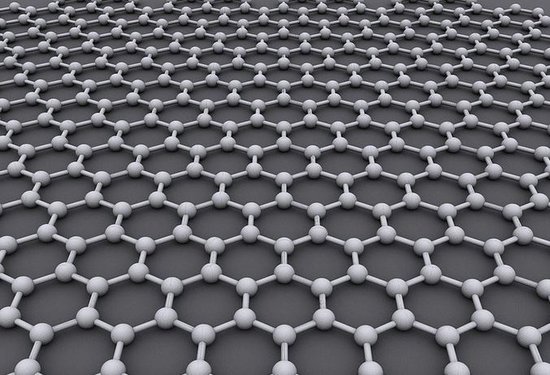

Unlike ITO, graphene is not fragile. It is a very flexible, thin and durable material and the fastest material to transfer heat and electricity.

The researchers used graphene on an OLED panel measuring 370 millimeters in length and 470 mm in width. The thickness of the team’s graphene electrodes was lass then 5 nanometers.

Given graphene’s flexibility and durability promise, the material could be key in the future development of flexible and custom shaped screens.

Cho Nam-sung, head of ETRI research team, was quoted by Korea Herald as saying that the commercialization of flexible OLED products can move forward by using the new material.

“It is meaningful that we are the first to apply graphene to OLED panels,” Cho said. “The technology would help elevate Korea’s OLED panel technology by widening the technology gap with Chinese rivals.”

One of the world’s most prominent makers of OLED panels, LG, said that graphene could help make flexible OLED screens a reality.

“Companies are making similar efforts to develop fordable display panels by minimizing the use of ITO electrodes by applying other materials such as plastics,” a spokesman at LG Display told Korea Herald.

“If commercialized soon, the graphene electrode technology would help the industry achieve fordable panels significantly.”

One of the main challenges will be mass-producing the material, given the high cost of manufacturing.

However, progress is being made. Earlier this year scientists at Kansas State University outlined a way to mass produce graphene by using a contained detonation of carbon-containing materials.

Christopher M. Sorensen, lead inventor of the method, was quoted by Futurism as saying:

“We have discovered a viable process to make graphene.”

“Our process has many positive properties, from the economic feasibility, the possibility for large-scale production and the lack of nasty chemicals.

“What might be the best property of all is that the energy required to make a gram of graphene through our process is much less than other processes because all it takes is a single spark.”