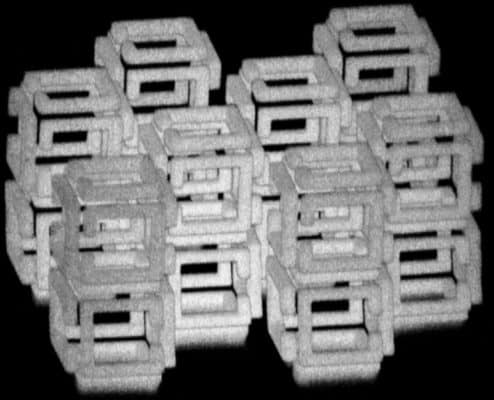

Scientists at MIT have found a way to shrink objects to one-thousandth of their original size. They can now fabricate nanoscale 3-D objects of virtually any shape. Nanoscale means so small – microscopic – that we measure it in nanometer. One nanometer equals one thousand-millionth of a meter (1 x 10-9).

The researchers say that they can also pattern the objects with several different materials, including metals and quantum dots. They can also pattern the objects with DNA. They wrote about their work in the journal Science (citation below).

Edward Boyden said:

“It’s a way of putting nearly any kind of material into a 3-D pattern with nanoscale precision.”

Boyden is an Associate Professor of Biological Engineering and Brain and Cognitive Sciences at the MIT McGovern Institute and the MIT Media Lab.

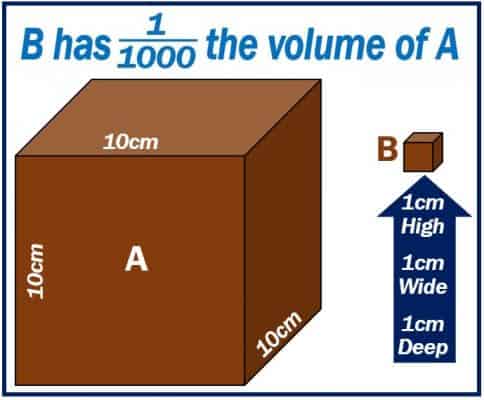

With their new technique, the scientists can create any structure and shape they want. They do this by patterning a polymer scaffold with a laser. After they have attached other useful materials to the scaffold, they then shrink it. The volume of the structure they create is one-thousandth of the original.

Potential application of technology

These super-tiny structures could have applications in medicine, robotics, optics, and many other fields, the authors say.

Their technique uses equipment that exists in many materials science and biology labs. Therefore, it would be widely accessible for scientists who would like to shrink objects.

Implosion fabrication

Current techniques that scientists use to shrink objects are limited in what they can do. Etching patterns onto a surface with light, for example, can produce 2-D structures. However, it does not work for 3-D structures.

We can make 3-D nanostructures by adding layer after layer. In other words, one layer on top of the other, and then another layer, etc. However, this process is challenging and extremely slow. And while there are methods that can directly 3-D print nanoscale objects, we can only use specialized materials such as plastic and polymers. These materials do not have the functional qualities we need for many applications.

Also, they are only able to generate self-supporting structures. For example, the technique can yield a solid pyramid, but not a hollow sphere or linked chain.

Expansion microscopy

Prof. Boyden and his students decided to a adapt a technique that his laboratory had developed a few years ago to overcome these limitations. The technique was for high-resolution brain tissue imaging. This technique is called expansion microscopy.

Expansion microscopy involves embedding tissue into a hydrogel and subsequently expanding it. This allows for high resolution with regular microscopes.

Hundreds of research teams in medicine and biology currently use expansion microscopy since it enables 3-D visualization of tissues and cells with ordinary laboratory equipment.

Reversing the process to shrink objects

The researchers found that by reversing this process, they could create large-scale objects expanded in hydrogels. They could then shrink them to the nanoscale. We call this approach ‘implosion fabrication.’

The scientists used a very absorbent material made of polyacrylate, as they did for expansion microscopy. Polyacrylate can absorb 500 to 1,000 times its mass in water. Diaper manufacturers use polyacrylate. The research team used the polyacrylate as the scaffold for the nanofabrication process.

The researchers bathed the scaffold in a solution that contained fluorescein molecules. When a laser light activated them, the molecules attached to the scaffold.

Using two-photon microscopy, the researchers attached the fluorescein molecules to specific locations inside the gel. Two-photon microscopy allows for precise targeting of locations deep within a structure.

Acting as anchors, the fluorescein molecules can bind to other types of molecules, the authors said.

Prof Boyden said:

“You attach the anchors where you want with light, and later you can attach whatever you want to the anchors,. It could be a quantum dot, it could be a piece of DNA, it could be a gold nanoparticle.”

Like film photography

Co-author Daniel Oran, a graduate student, said:

“It’s a bit like film photography – a latent image is formed by exposing a sensitive material in a gel to light. Then, you can develop that latent image into a real image by attaching another material, silver, afterwards”

“In this way implosion fabrication can create all sorts of structures, including gradients, unconnected structures, and multimaterial patterns.”

Adding an acid to shrink objects

As soon as the target molecules were attached in the right places, the scientists added an acid to shrink the entire structure. The acid blocked the polyacrylate gel’s negative charges so that they could no longer repel each other. This caused the gel to shrink.

Using this technique, the scientists can shrink objects ten-fold in each dimension. Therefore, there is a 1,000-fold reduction in volume.

This ability to shrink objects allows for greater resolution. It also makes it possible to assemble materials in a low-density scaffold. “This enables easy access for modification, and later the material becomes a dense solid when it is shrunk,” the authors wrote.

Using existing systems to shrink objects

Co-author Samuel Rodriques, a graduate student, said:

“People have been trying to invent better equipment to make smaller nanomaterials for years, but we realized that if you just use existing systems and embed your materials in this gel, you can shrink them down to the nanoscale, without distorting the patterns.”

At the moment, the scientists can create objects at around one cubic millimeter, patterned with a 50-nanometer resolution. There is a trade-off between resolution and size. They can achieve a resolution of approximately 500 nanometers with one cubic centimeter objects.

With further refinement of the process, however, they could improve the resolution, the authors say.

Potential applications

The authors believe that this technology might have applications in optics. For example, for making specialized lenses that scientists could use to study light’s fundamental properties.

Optics is the branch of physics that studies the properties and behavior of light.

The technique could also allow for fabrication of smaller and better lenses for use in mobile phone cameras. Microscopes and endoscopes might also benefit from smaller lenses.

One day, the researchers said, their approach may lead to the creation of nanoscale robots or electronics. Robots are machines or devices that we can usually program. We program them to do specific things, i.e., certain tasks.

Prof. Boyden said:

“There are all kinds of things you can do with this. Democratizing nanofabrication could open up frontiers we can’t yet imagine.”

Many research laboratories already have the equipment necessary for this kind of fabrication.

Prof. Boyden added:

“With a laser, you can already find in many biology labs, you can scan a pattern, then deposit metals, semiconductors, or DNA, and then shrink it down.”

Citation

“3D nanofabrication by volumetric deposition and controlled shrinkage of patterned scaffolds,” Edward S. Boyden, Daniel Oran, Samuel G. Rodriques, Adam H. Marblestone, Ruixuan Gao, Shoh Asano, Paul W. Tillberg, Mark A. Skylar-Scott, and Fei Chen. Science, 14 Dec 2018: Vol. 362, Issue 6420, pp. 1281-1285. DOI: 10.1126/science.aau5119.