Robotic systems with rigid parts can be a threat to humans who work alongside them. Contrastingly, recently flourishing soft actuators and robots offer ideal adaptivity to surroundings. They also offer safe, coexisting interactions with nearby humans.

However, they are not so good at lifting, carrying, or handling heavy objects. The inherent low-stiffness nature of silicone rubbers and other soft materials undermines their load-bearing competence.

SMPs stand out as promising candidates in the search for stiffness-tunable materials with a good weight bearing capacity. The letters SMPs stand for Shape Memory Polymers. With SMPs, stiffness-tunable materials do not lose their compliance while robots are working with objects.

SMPs for stiffness-tunable materials – pros & cons

Pros

SMPs have two features that make them good candidates in our search for stiffness-tunable materials with good load capacity:

- They can reversibly change stiffness by up to three orders of magnitude.

- They are compatible with 3D printing.

Cons

However, so far, researchers say that SMP-based soft actuators have some downsides:

- Their responses can be slow.

- There are small deformations.

- There are problems in automated fabrications with microfeatures.

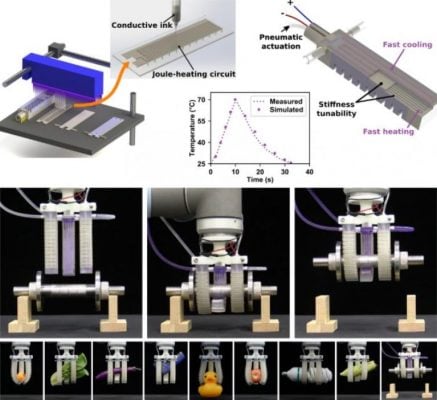

A team of researchers recently proposed a paradigm to use hybrid multimaterial 3D printing and fine-element simulations to design and create fast-response, stiffness-tunable soft actuators. They can change from soft to stiff within thirty-two seconds.

The researchers, from Shanghai Jiao Tong University (SJTU) and the Singapore University of Technology and Design (SUTD), wrote about their work in the journal Advanced Functional Materials (citation below).

Co-project leader, Qi (Kevin) Ge, an Assistant Professor from SUTD’s Science and Math Cluster, said:

“We combine a commercial inkjet multimaterial 3D printing technology with the direct-ink writing approach to fabricate our fully printed FRST actuator. The stiffness tunability is provided by an embedded SMP layer, and the fast response is enabled by embedded heating and cooling elements.”

Impressive stiffness enhancement

The integration of the SMP layer into the actuator body improves its stiffness by up to 120 times. It also does this without any flexibility or adaptivity loss.

According to a SUTD press release:

“A deformable conductive circuit printed with a silver nanoparticle ink activates the rubbery state of the SMP by localized Joule-heating. Upon deforming the actuator with pressurized air, the SMP is cooled down with coolant driven through a fluidic channel to lock the geometry.”

Prof. Ge said:

“The deformed actuator in its stiff state can perform load-carrying tasks, even after releasing the pressurized air. More importantly, a heating-cooling cycle can be completed within about half a minute, which is the fastest rate reported, to our knowledge.”

Computational models

Co-first author, Yuan-Fang Zhang, a Postdoctoral Researcher at SUTD, added:

“We have also built computational models to simulate the mechanical and thermal-electrical behaviors of our FRST actuator.”

“Once validated with experiments, the models are used to guide the design of FRST actuator and provide insights into enhancement of load capacity.”

Overall, the designs of the fluidic microchannel layer and the Joule-heating circuit reduce the heating-cooling cycle to approximately 30 seconds. This enhances the practicability of the thermally-responsive stiffness-tunable soft actuator significantly. It renders it suitable for additional applications.

Project co-leader at SJTU, Prof. Gu, said:

“To showcase the high load capacity and shape adaptivity of our prototype, we have devised a robotic gripper with three FRST actuators that can grasp and lift objects with arbitrary shapes and various weights spanning from less than 10 g to up to 1.5 kg.”

What is 3D printing?

3D printing is a type of manufacturing that adds or deposits layer after layer until it has completed the finished product. It is a type of additive manufacturing.

3D printing contrasts with subtractive manufacturing, which works the other way round. Subtractive manufacturing starts with an object, such as a block of metal, and continuously remove bits until it has the finished product.

With 2D printing or additive manufacturing, we start with nothing and end up with something. With subtractive manufacturing, on the other hand, we start with something and end up with something smaller.

Citation

“Fast‐Response, Stiffness‐Tunable Soft Actuator by Hybrid Multimaterial 3D Printing,” Yuan‐Fang Zhang, Ningbin Zhang, Hardik Hingorani, Ningyuan Ding, Dong Wang, Chao Yuan, Biao Zhang, Guoying Gu, and Qi Ge. Advanced Functional Materials, First published: 08 January 2019. DOI: https://doi.org/10.1002/adfm.201806698.