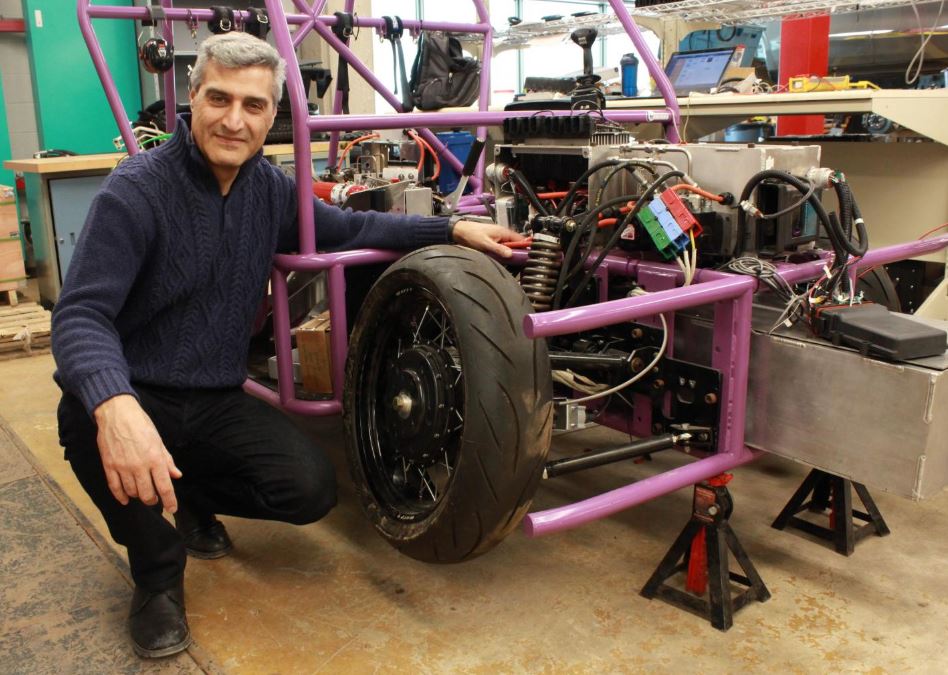

A new, sophisticated, self-contained wheel unit could reduce vehicle costs, say researchers at the University of Waterloo. The new unit combines a wheel and an electric motor. It also has a suspension, steering, and braking system in a single module that can be bolted onto any type of vehicle frame.

Manufacturers would no longer have to spend vast sums of money developing these components from scratch. They would be able to produce specialized vehicles much more cheaply, and even in small quantities.

The researchers wrote about their work in the Journal of Automotive Engineering (citation below). The authors were Mohammad-Amin Rajaie, Amir Khajepour, Alireza Pazooki, and Amir Soltani.

Wheel unit – a full vehicle with just one wheel

Amir Khajepour, a Mechanical and Mechatronics Engineering Professor at Waterloo, said:

“The idea is modularity and plug-and-play control capability. Our wheel unit, in a sense, is a full vehicle with only one wheel. All that’s missing is a body.”

Automotive researchers initially applied the concept to two-seater, electric urban cars, which promise to reduce pollution and ease congestion. However, they only make up a tiny proportion of sales because of space limitations and safety concerns. They are also very expensive.

A mass-produced wheel unit could reduce production costs significantly. It would also create passenger space that would otherwise be used for mechanical components such as steering columns.

In a press release, the University of Waterloo wrote:

“To improve the stability of the tall, narrow cars, researchers also designed and prototyped the units – which weigh about 40 kilograms and have about 25 horsepower – to enable active wheel cambering, or tilting.”

Prof. Khajepour, Director of the Mechatronic Vehicle Systems Lab, said:

“Companies will be able to produce a smaller car that is cheaper, too. Right now, we are not there. You have to pay more to get a smaller car, to get less.”

Scaling up the wheel unit

The researchers say that their next step is not scale up the wheel unit with customized bodies in the fields of rescue operations, forestry, and mining.

Prof Khajepour said:

“It’s an economy of scale problem. Corner modules would allow us, without enormous development costs, to make vehicles that are specific for each application, for each function, by concentrating only on the design of the body and the user interface.”

Citation

“Development of A Novel Integrated Corner Module for Narrow Urban Vehicles,” Mohammad-Amin Rajaie, Amir Khajepour, Alireza Pazooki, and Amir Soltani. Journal of Automotive Engineering Volume: 233 issue: 3, page(s): 548-556. DOI: https://doi.org/10.1177/0954407017748810.