Coating graphene with wax during the manufacturing of devices reduces surface wrinkles. A reduction in wrinkles makes for a less contaminated surface.

A team of researchers explained in the journal Nature Communication (citation below) how wax helps reduce performance-impairing wrinkles. The authors, from Massachusetts Institute of Technology (MIT) and Tufts University, were Wei Sun Leong, Haozhe Wang, Jingjie Yeo, Francisco J. Martin-Martinez, Ahmad Zubair, Pin-Chun Shen, Yunwei Mao, Tomas Palacios, Markus J. Buehler, Jin-Yong Hong, and Jing Kon.

Graphene is the world’s lightest, toughest, and thinnest material. It is just one-atom thin. It is a super conductor of heat and electricity. Graphene is surprisingly flexible; an unusual trait for tough and hard materials. It holds promise for making next-generation electronics.

Scientists are researching the material for uses in quantum computers, circuits for flexible electronics, and many other devices.

However, removing the fragile material from the substrate on which it is grown and transferring it to a new substrate is extremely tricky.

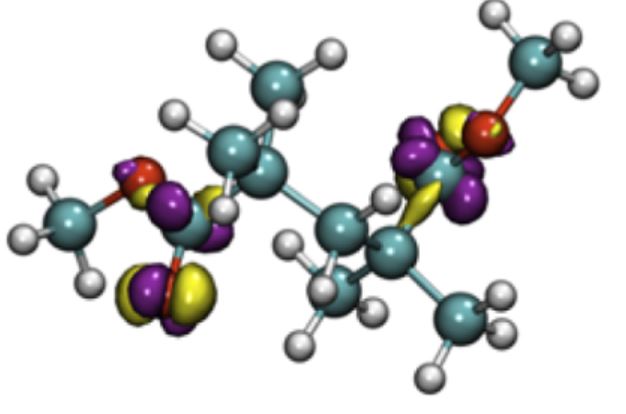

Traditionally, researchers have encased graphene in a polymer. The polymer protects it against breakage. However, the polymer also introduces defects and particles into the material’s surface. These interrupt the flow of electricity and undermine performance.

Coating graphene with wax and heating it up

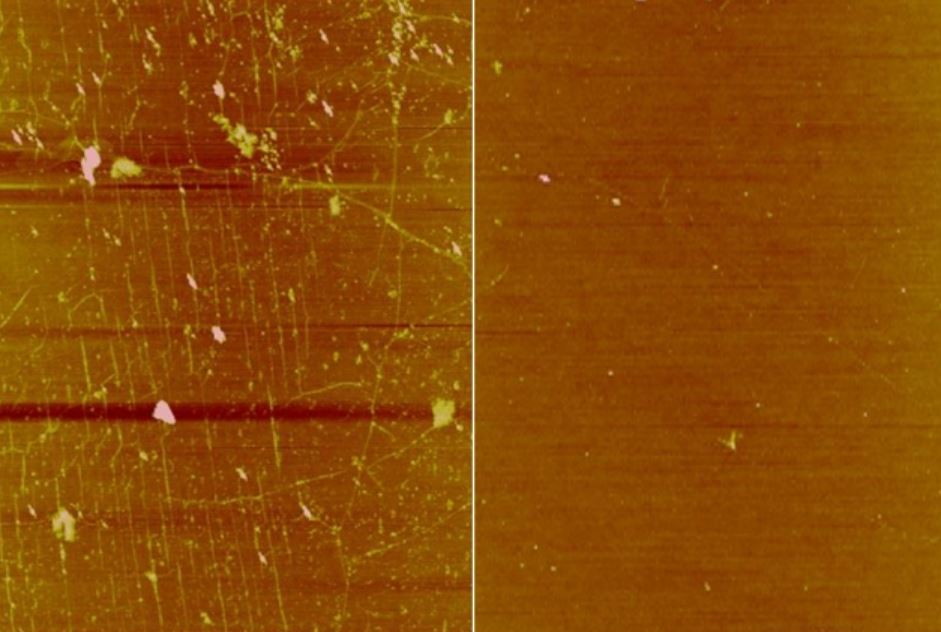

By coating graphene with wax and then heating it up, its surface smooths out. Therefore, there are fewer wrinkles. The graphene coating can also be washed away without leaving that much residue.

In experiments, their wax-coated graphene performed four times better compared to graphene in the traditional polymer-protecting layer. ‘Performance,’ in this context, refers to ‘electron mobility.’ In other words, how fast electrons move across the graphene’s surface. Surface defects slow them down.

First author Wei Sun Leong, a PostDoc at MIT’s Department of Electrical Engineering and Computer Science (EECS), said:

“Like waxing a floor, you can do the same type of coating on top of large-area graphene and use it as a layer to pick up the graphene from a metal growth substrate and transfer it to any desired substrate.”

“This technology is very useful because it solves two problems simultaneously: the wrinkles and polymer residues.”

Coating graphene with wax involved ‘thinking outside the box’

Co-first author, Haozhe Wang, a Doctoral Student at EECs, said that using wax might sound like a natural solution, but it required some thinking outside the box (outside the lab).

Wang said:

“As students, we restrict ourselves to sophisticated materials available in lab. Instead, in this work, we chose a material that commonly used in our daily life.”

In an MIT News article, Rob Matheson explains what the researchers did in more detail.

Citation

“Paraffin-enabled graphene transfer,” Wei Sun Leong, Haozhe Wang, Jingjie Yeo, Francisco J. Martin-Martinez, Ahmad Zubair, Pin-Chun Shen, Yunwei Mao, Tomas Palacios, Markus J. Buehler, Jin-Yong Hong, and Jing Kong. Nature Communications, Volume 10, Article Number: 867 (2019). DOI: https://doi.org/10.1038/s41467-019-08813-x.

Video – What is Graphene?

This Market Business News video explains in simple terms what graphene is.