Ten percent of the cement we use in concrete could come from crushed mining waste, say researchers from the Technical University Of Denmark (Danmarks Tekniske Universitet – DTU). Adding the mining waste would not undermine the strength of the materials.

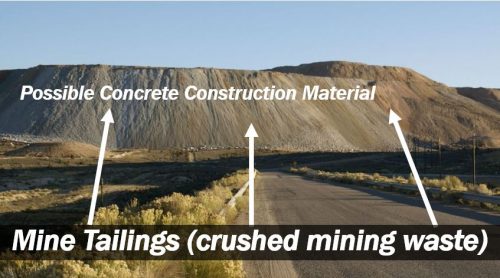

Giant piles of mining waste worldwide are waiting for the cement industry to resurrect them.

Scientists at DTU Civil Engineering showed that mine tailings could replace up to 10% of cement. Mine tailings are remnants of the crushed ore after the extraction of metals and other substances.

Using mining waste – mine tailings – could significantly reduce the cement industry’s emissions of greenhouse gases. Five percent of human emissions of carbon dioxide comes from the cement industry.

Greenhouse gases are atmospheric gasses that absorb and emit radiation. In other words, they keep Earth’s surface warm. Carbon dioxide or CO2, for example, is a greenhouse gas.

Analysis of crushed mining waste

Pernille Erland Jensen said:

“We’ve performed physical and mineralogical analyses of mine tailings from mines in all parts of the world. The results show that a large selection of the samples have great potential to replace up to ten percent of the cement used in concrete, while other mine tailings have properties which mean that they can only be used as filler.”

Jensen is an Associate Professor at DTU’s Department of Civil Engineering.

The Danish Construction Association has supported this latest study. Consultant Anne Rosenskilde Lajer characterized the project as extremely relevant to the Danish construction industry. The industry, Lajer added, needs new, innovative materials that it can use as additives in concrete.

Using mining waste – benefits

Prof. Jensen points out that exploiting mining waste has two main benefits:

- It has potential as a raw material for concrete.

- It can solve environmental problems from mining waste. Additionally, it can reduce carbon dioxide from cement production.

Prof. Jensen said:

“The interesting thing about these mine tailings is that they’re deposited in such quantities that if they’re used globally, this can make a real difference to the climate impact from the construction industry, because we reduce the amount of cement used when tailings can become a substitute in concrete production.”

According to a DTU press release:

“Mechanical tests of mine tailings from mines all over the world performed at DTU Civil Engineering have documented that a large share of the world’s mining waste can be used in concrete without compromising the strength of the concrete.”

“But before mine tailings can be used, there is a need for more knowledge about the chemical properties of the materials and about whether they constitute an environmental pollution risk.”

The chemistry of mining waste

In this latest study, Anne Mette Tholstrup Simonsen studied the chemistry of raw mine tailings. She also studied their chemistry when the mining waste was used in concrete. Simonsen is a Research Assistant at DUT’s Department of Engineering.

The researchers gathered and analyzed data on mine tailings from thirteen different mines across the world.

Simonsen said:

“Analyses show us whether we can recommend that some mine tailings are used unprocessed or whether they’re to be treated before they’re added to concrete.”

“We’ve tested whether heavy metals will subsequently occur in too high concentrations, and whether they are leached out from concrete if it comes into contact with water.”

“We’ve studied leaching from whole pieces of concrete and small grains – where we crush the concrete – so we know how concrete from a demolished building behaves if, for example, it is used as road fill.”

Positive effect on climate

DTU Management’s calculations showed that using mining waste reduces the cement industry’s CO2 emissions. Even after transporting the waste over long distances, CO2 emissions are still lower.

You would need to transport the mining waste about 20,000 kilometers (12,427 miles) before there were no reductions in CO2 emissions.

DTU wrote:

“Treatment of mining waste before it is used as a component in concrete can be performed using a number of methods such as electrochemical cleaning and electrochemical bath.”

”Future development and analysis of various treatment methods are to clarify whether there are economic and environmental gains which make it attractive to utilize mining waste despite the processing required.”

“In addition, the researchers want to include even more different tailings in their analysis to support the statistical basis for their conclusions further.”