Graphene can now be produced much more cheaply, say scientists from the University of Glasgow, who managed to produce large-area graphene about 100 times cheaper than ever before. This could open the way for commercially-viable new technologies that may change the lives of people with limb prostheses.

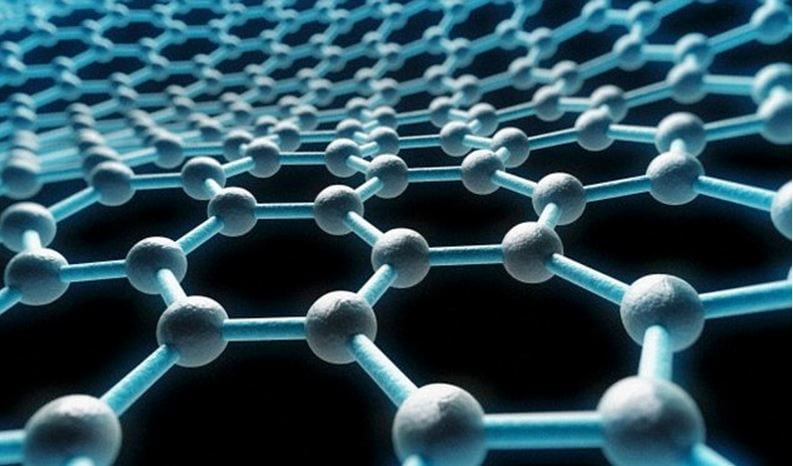

Graphene, which was first isolated from graphite in 2004, is considered a wonder material by scientists. It is just a single atom thick, flexible, 207 times stronger than steel, and can efficiently conduct electricity and heat.

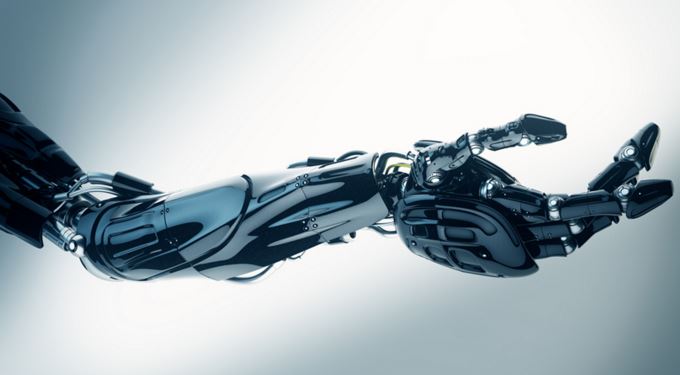

However, its super-high cost of production has limited its widespread industrial adoption. If graphene production prices can be reduced, it could be used in several industries and medical applications. It could, for example, by used to make synthetic skin that would provide sensory feedback for patients with limb prostheses.

Graphene, a 1-atom thick virtually 2-D material, is 207 times tougher than steel.

Graphene, a 1-atom thick virtually 2-D material, is 207 times tougher than steel.

Team leader, Dr. Ravinder Dahiya, who works at the University of Glasgow’s School of Engineering, and colleagues explained in the scientific journal Scientific Reports how they found a way to produce large sheets of graphene using the same cheap copper used in the manufacturing of lithium–ion batteries in many household devices.

Graphene production one hundred times cheaper

According to the scientists, they have managed to bring down production costs to one-hundredth of what they were before the study.

Graphene is commonly produced by using a process called chemical vapour deposition (CVD), which converts gaseous reactants into a graphene film on a substrate (a special surface).

Dr. Dahiya and team used a similar process to make high-quality graphene across the surface of commercially-available copper foils of the kind frequently used as the negative electrodes in lithium-ion batteries.

Copper’s super-smooth surface provided an ideal bed upon which the graphene could form.

The authors also found that the electrical and optical performance of transistors they made using their graphene was significantly superior to similar material produced from the older process.

Commercially-viable graphene could be used to create synthetic skin that would make it much easier for people to control their limb prostheses.

Commercially-viable graphene could be used to create synthetic skin that would make it much easier for people to control their limb prostheses.

Top-quality graphene at low cost

Dr. Dahiya said:

“The commercially-available copper we used in our process retails for around one dollar per square metre, compared to around $115 for a similar amount of the copper currently used in graphene production. This more expensive form of copper often required preparation before it can be used, adding further to the cost of the process.”

“Our process produces high-quality graphene at low cost, taking us one step closer to creating affordable new electronic devices with a wide range of applications, from the smart cities of the future to mobile healthcare.”

“Much of my own research is in the field of synthetic skin. Graphene could help provide an ultraflexible, conductive surface which could provide people with prosthetics capable of providing sensation in a way that is impossible for even the most advanced prosthetics today.”

The researchers, who described their discovery as ‘very exciting’, say they are keen to continue their research.

University of Glasgow scientists worked alongside colleagues from Bilkent University in Turkey in this research.

The research was supported by the Engineering and Physical Sciences Council (EPSRC) and the European Commission.

Citation: “Synthesis of Large Area Graphene for High Performance in Flexible Optoelectronic Devices,” Emre O. Polat, Osman Balci, Nurbek Kakenov, Hasan Burkay Uzlu, Coskun Kocabas & Ravinder Dahiya. Scientific Reports. 18 November, 2015. DOI: 10.1038/srep16744.

Video – What is graphene?

This short animation, created by the University of Manchester and narrated by Dr. Sarah Haigh, explains how graphene was isolated and what it is.

Comments are closed.