Graphene can be produced one hundred times more cheaply using commercially-available copper for it to form on, scientists from the University of Glasgow claimed. Cheap, mass-produced graphene is seen as the Holy Grail for several new technologies. It is the strongest material we know of.

Graphene, for example, could be used to make artificial skin that would provide sensory feedback for limb prostheses (false limbs) that would dramatically change patients’ lives.

Graphene, which was initially isolated from graphite in 2004, is a 1-dimensional (1 atom-thick), super-light, flexible material that is 207 times stronger than steel. It is also an incredibly efficient conductor of electricity and heat.

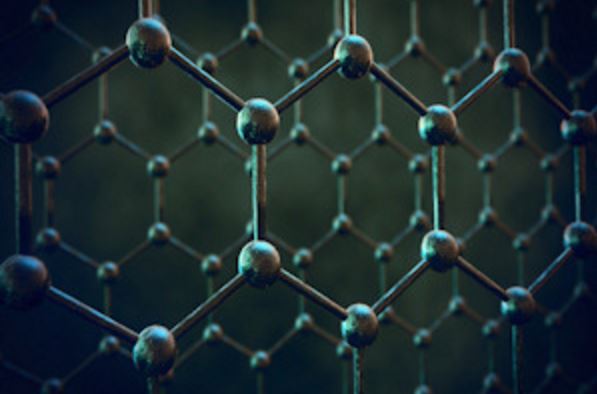

Graphene is a form of carbon consisting of planar sheets which are just one atom thick, with the atoms arranged in a honeycomb-shaped lattice. (Image: University of Manchester)

Graphene is a form of carbon consisting of planar sheets which are just one atom thick, with the atoms arranged in a honeycomb-shaped lattice. (Image: University of Manchester)

High-cost obstacle of graphene production overcome

The researchers explained in the open-access journal Scientific Reports that the main problem has been the cost of production, which hindered its widespread adoption by industry – that is, until now.

If graphene production became commercially viable, it could be used in a number of industries, including biological engineering, aerospace engineering, optical electronics, ultrafiltration, photovoltaic cells and energy storage.

The most popular way to produce graphene is through a process called CVD (chemical vapour deposition), a chemical process that converts gaseous reactants (substances that take part in and undergo change during a reaction) into a graphene film on a special surface (substrate).

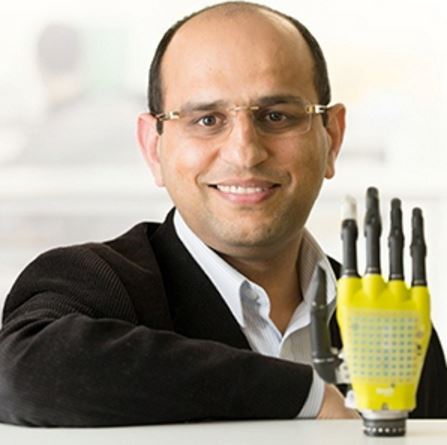

Team leader Dr. Ravinder Dahiya, from the School of Engineering at the University of Glasgow, and colleagues used a similar process to produce top-quality graphene across the surface of commercially-available copper foils of the type commonly used as the negative electrodes in lithium-ion batteries.

Copper has an ultra-smooth surface, making it an ideal material upon which graphene can form.

According to the authors, when they made electrical and optical transistors using the their graphene, their performance was considerably superior to similar material produced from the older process.

Dr. Dahiya says there are many potential uses for commercially-viable graphene. (Image: University of Glasgow)

Dr. Dahiya says there are many potential uses for commercially-viable graphene. (Image: University of Glasgow)

Top-grade graphene produced cheaply

Dr. Dahiya explained:

“The commercially-available copper we used in our process retails for around one dollar per square metre, compared to around $115 for a similar amount of the copper currently used in graphene production. This more expensive form of copper often required preparation before it can be used, adding further to the cost of the process.”

“Our process produces high-quality graphene at low cost, taking us one step closer to creating affordable new electronic devices with a wide range of applications, from the smart cities of the future to mobile healthcare.”

“Much of my own research is in the field of synthetic skin. Graphene could help provide an ultraflexible, conductive surface which could provide people with prosthetics capable of providing sensation in a way that is impossible for even the most advanced prosthetics today.”

Dr. Dahiya and team, who described their achievement as ‘very exciting’, are keen to carry on with their research.

The scientists at the University of Glasgow worked together with researchers from Bilkent University in this research.

The study was finance by the European Commission and the EPSRC (Engineering and Physical Sciences Research Council).

Reference: “Synthesis of Large Area Graphene for High Performance in Flexible Optoelectronic Devices,” Nurbek Kakenov, Emre O. Polat, Osman Balci, Ravinder Dahiya, Hasan Burkay Uzlu and Coskun Kocabas. Scientific Reports. 18th November, 2015. DOI: 10.1038/srep16744.