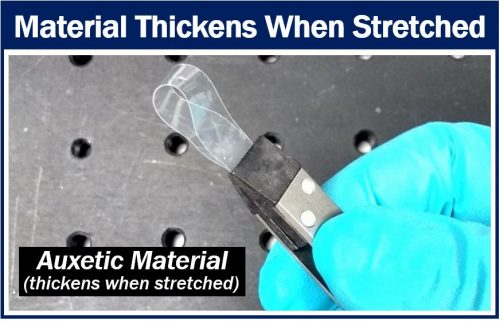

Scientists at the University of Leeds have discovered a material that thickens as you stretch it. It is the first synthetic material that thickens – at a molecular level – as it stretches.

Researchers from the University of Leeds, University of Manchester, and UltraVision CLPL wrote about the new material in the journal Nature Communications (citation below).

Dr. Devesh Mistry and colleagues discovered a new non-porous material. Dr. Mistry is the lead author for this research. He undertook this research while completing his PhD at the University of Leeds’ School of Physics and Astronomy.

The material has inherent ‘auxetic’ stretching qualities. Auxesis refers to growth in plant or animal tissues resulting from an increase in cell size without cell division.

Cat skin, for example, exhibits auxetic capabilities. The tendons in the human body and the protective layer in mussel shells also exhibit auxetic capabilities.

Researching materials that thicken when stretched

Scientists have been actively researching synthetic auxetic materials for over three decades. However, they have only been able to create them by structuring conventional materials using 3D printing and other complex engineering processes.

Not only are these processes time consuming and expensive, but they can also lead to weaker, porous products.

For material scientists and physicists, identifying a synthetic molecular version of a material that thickens when pulled is a major step forward. It is also a huge step forward for development companies.

However, the authors acknowledge that they need to research the material further. They need to understand what drives the auxetic behavior. They also want to determine what its commercially viable applications might be.

Viable, in this context, means capable of generating profits year after year.

Dr. Mistry said:

“This is a really exciting discovery, which will have significant benefits in the future for the development of products with a wide range of applications.”

“This new synthetic material is inherently auxetic on the molecular level and is therefore much simpler to fabricate and avoids the problems usually found with engineered products. But more research is needed to understand exactly how they can be used.”

Auxetic materials thicken when we stretch them

Dr. Mistry added:

“When we stretch conventional materials, such as steel bars and rubber bands they become thinner. Auxetic materials, on the other hand, get thicker.”

“Auxetics are also great at energy absorption and resisting fracture. There may be many potential applications for materials with these properties including body armor, architecture and medical equipment. We have already submitted a patent and are talking to industry about the next steps.”

Examining the potential of liquid crystal elastomers

The researchers discovered the new material while they were examining the capabilities of liquid crystal elastomers.

We use liquid crystals in mobile phones and TV screens. They have both solid and liquid properties. When liquid crystals are linked with polymer chains, they form rubbery networks. These networks have completely new properties as well as new applications.

New use for liquid crystals

Co-author, Prof. Helen Gleeson, said:

“Our results demonstrate a new use for liquid crystals beyond the flat screen monitors and televisions many of us are familiar with.”

“This new synthetic material is a great example of what physics research and exploring the potential of materials such as liquid crystals can discover. Collaboration between scientists with several areas of expertise and the extensive technical facilities we have at Leeds make this kind of exploration and discovery possible.”

Prof. Gleeson is Head of Physics and Astronomy at Leeds. Her areas of expertise include liquid crystals, sensors, soft matter, self-assembly, and photonic materials.

Testing material when it thickens and stretches to its limits

The instruments and expertise of the staff at LEMAS enabled the researchers to test the new material rigorously. LEMAS stands for the Leeds Electron Microscopy and Spectroscopy Centre.

Regarding the tests that the LEMAS staff carried out, Professor Gleeson said:

“We wanted to be sure the material wouldn’t break down or become porous when stretched to its limits. Our LEMAS center had the tools to do this.”

Citation

“Coincident molecular auxeticity and negative order parameter in a liquid crystal elastomer,” D. Mistry, S. D. Connell, S. L. Mickthwaite, P. B. Morgan, J. H. Clamp, and H. F. Gleeson. Nature Communications, volume 9, Article number: 5095 (2018). DOI:https://doi.org/10.1038/s41467-018-07587-y.