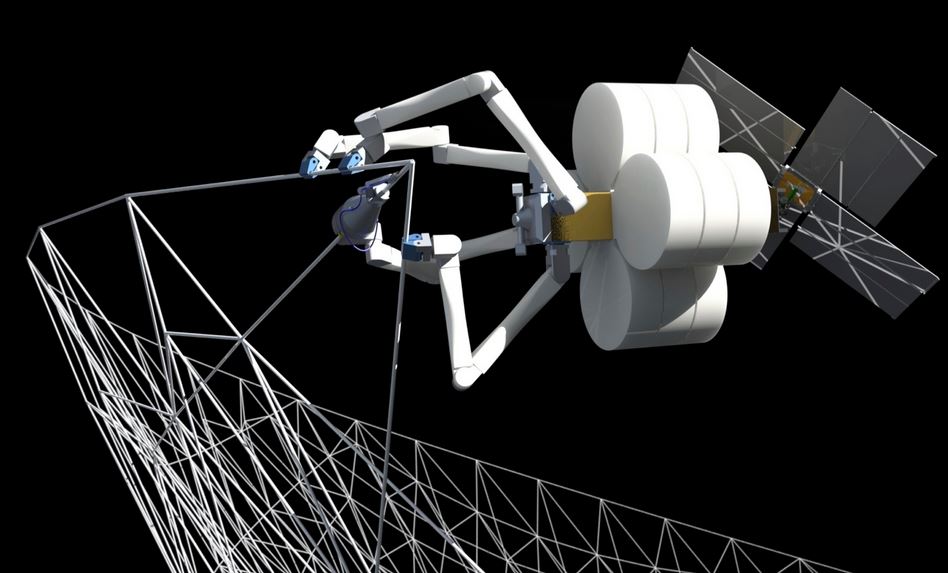

Robot spiders will work as droids building spaceships and space stations in orbit and eventually also in deep space, instead of having to transport cumbersome structures from the Earth’s surface, thus achieving a considerable reduction in costs and allowing for greater flexibility in spacecraft design, says Tethers Unlimited, a US private aerospace firm which has NASA backing.

Spider-Fab, a NASA-funded program, aims to use spider-like droids to construct large objects initially in orbit and then further away.

Tethers Unlimited Inc. (TUI) is currently developing a suite of technologies to enable on-orbit construction of large spacecraft components such as trusses, solar panels, antennas and other multi-functional structures.

The spider robots will be able to fabricate large structures in space, saving money and allowing for more flexible spacecraft and space-station designs. (Image: TUI)

TUI says SpiderFab offer “order-of-magnitude packing- and mass-efficiency improvements over current deployable structures and enables construction of kilometer-scale apertures within the current launch vehicle capabilities, providing higher-resolution data at lower life-cycle costs.”

Currently, considerable resources are dedicated to launching mass space systems from Earth into orbit. This is particularly true for systems with physically large components such as panels, booms and antennas, which need to be designed to stow for launch and then be deployed when in orbit.

The aperture sizes and spacecraft structures are limited by the requirement to stow them within rockets.

Building in space a designer’s dream

If these large structures could be built in space, not only would enormous savings be achieved, but also the design of spacecraft and space stations would be less limited.

TUI wrote:

“TUI is developing an architecture and a suite of technologies for automated on-orbit construction of very large structures and multifunctional space system components, such as kilometer-scale antenna reflectors.”

“This process will enable space systems to be launched in a compact and durable ‘embryonic’ state. Once on orbit, these systems will use techniques evolved from emerging additive manufacturing and automated assembly technologies to fabricate and integrate components such as antennas, shrouds, booms, concentrators, and optics.”

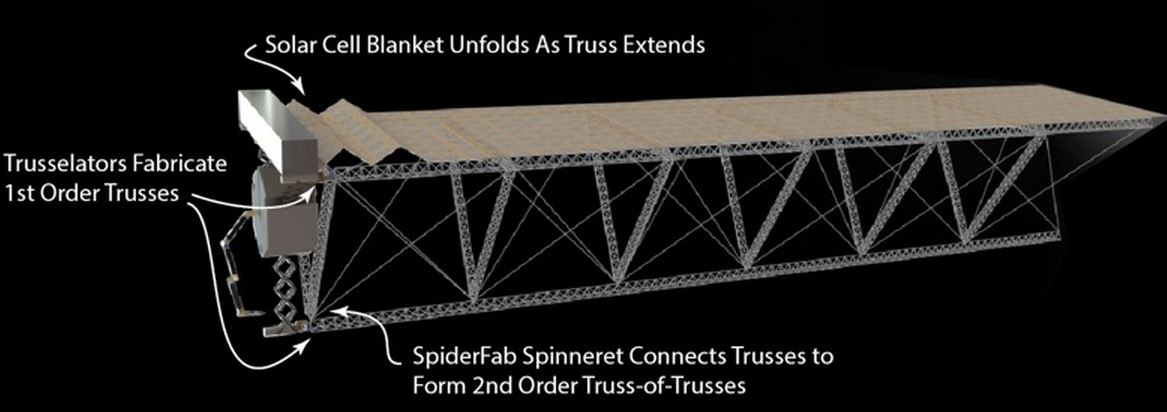

TUI is using a machine that uses 3D printing techniques and robotic assembly to build long, high-performance truss structures. (Image: TUI)

“The primary benefit of this on-orbit fabrication capability will be order-of-magnitude improvements in packing efficiency and system mass, which will enable NASA to use small, low-cost launch vehicles to deploy systems dramatically larger than possible with current state-of-the-art technologies.”

The net benefit for NASA will be enormous. It will be able to acquire and distribute a range of forms of data at higher resolution, greater bandwidth, higher signal-to-noise, and lower life-cycle cost.

The Trusselator Effort

TUI is currently implementing the first step in the SpiderFab architector – a machine that uses robotic assembly and 3-D printing to build long, high-performance truss structures.

The ‘Trusselator’ device will facilitate the construction of large support structures for systems such as football-sized antennas, large solar sails, and multi-hundred-kilowatt solar arrays.

Citation: “SpiderFab: An Architecture for Self-Fabricating Space Systems,” Robert P. Hoyt, Jesse I. Cushing, Jeffrey T. Slostad, Greg Jimmerson, Todd Moser, Greg Kirkos, Mark L. Jaster and Nestor R. Voronka. Tethers Unlimited, Inc., Bothell WA, 98011, USA.

Interesting related article: “What is a robot?”