Spray-on antennas, made from MXene ‘spray paint,’ could unlock the potential of smart, connected technology. We hear a lot about the promise of the Internet of Things, wearables, and functional fabrics. However, one of the main reasons for their delayed arrival is the challenge of seamlessly integrating connection technology. Specifically, integrating antennas with flexible shape-shifting ‘things.’

However, a breakthrough by scientists in Drexel’s College of Engineering may be about to change all that. Kapil Dandekar and colleagues say that they have found a way of installing spray-on antennas.

Kapil Dandekar, PhD, is a professor of Electrical and Computer Engineering in Drexel’s College of Engineering. He directs the Drexel Wireless Systems Lab.

Prof. Dandekar and colleagues wrote about their spray-on antennas in the journal Science Advances (citation below). His study colleagues and co-authors were Asia Sarycheva, Alessia Polemi, Yuqiao Liu, Babak Anasori1, and Yury Gogotsi. They are all from Drexel University’s Department of Materials Science and Engineering.

Spray-on antennas are invisibly thin

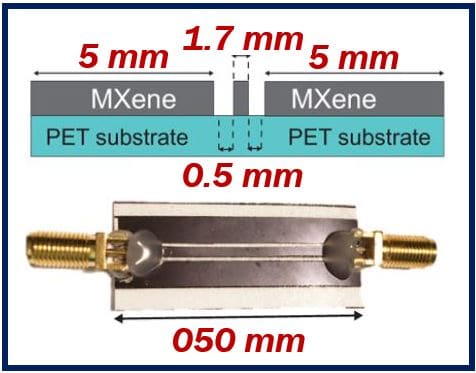

The authors explain how they developed a method for creating invisibly thin spray-on antennas. They are made of MXene, a type of two-dimensional, metallic material.

They say their antennas perform as well as those we use in portable transducers, wireless routers, and mobile devices.

Prof. Dandekar said:

“This is a very exciting finding because there is a lot of potential for this type of technology.”

“The ability to spray an antenna on a flexible substrate or make it optically transparent means that we could have a lot of new places to set up networks – there are new applications and new ways of collecting data that we can’t even imagine at the moment.”

Material has exceptional conductivity

When you place the MXene titanium carbide in water, it dissolves and subsequently creates a paint or ink. The material’s exceptional conductivity enables it to transmit and direct radio waves. It does this even if you apply a very thin coating.

Regarding the ability of the spray-on antennas to communicate efficiently, Asia Sarycheva said:

“We found that even transparent antennas with thicknesses of tens of nanometers were able to communicate efficiently.”

“By increasing the thickness up to 8 microns, the performance of MXene antenna achieved 98 percent of its predicted maximum value.”

Asia Sarycheva is a doctoral candidate in the A.J. Drexel Nanomaterials Institute and Materials Science and Engineering Department.

Being able to preserve transmission quality in a form this thin is significant. It means that we can embed the antennas easily. In other words, we would have spray-on antennas that we could use for a wide variety of objects and surfaces.

The objects would not need to have a certain level of rigidity. Also, we would not be adding any significant weight or circuitry.

Critical for the Internet of Things

Prof. Dandekar said:

“This technology could enable the truly seamless integration of antennas with everyday objects which will be critical for the emerging Internet of Things.”

“Researchers have done a lot of work with non-traditional materials trying to figure out where manufacturing technology meets system needs, but this technology could make it a lot easier to answer some of the difficult questions we’ve been working on for years.”

Testing the spray-on antennas

Initial tests showed that the spray-on antennas can perform as well as current antennas. Common antennas are made of familiar metals. Familiar metals are, for example, copper, aluminum, silver, and gold. Metal antennas are much thicker than MXene antennas.

Scientists and electrical engineers have been trying to create smaller and lighter antennas for a long time. Hence, this discovery represents a huge step forward “both in terms of reducing their footprint as well as broadening their application,” the authors wrote.

Why the researchers selected MXene

Yury Gogotsi said:

“Current fabrication methods of metals cannot make antennas thin enough and applicable to any surface, in spite of decades of research and development to improve the performance of metal antennas.”

“We were looking for two-dimensional nanomaterials, which have sheet thickness about hundred thousand times thinner than a human hair; just a few atoms across, and can self-assemble into conductive films upon deposition on any surface.”

“Therefore, we selected MXene, which is a two-dimensional titanium carbide material, that is stronger than metals and is metallically conductive, as a candidate for ultra-thin antennas.”

Yury Gogotsi, PhD, is a Distinguished University and Bach Professor of Materials Science and Engineering in the College of Engineering, and Director of the A.J. Drexel Nanomaterials Institute. He initiated and led the project.

Drexel scientists discovered the family of MXene materials seven years ago. They have been gaining an understanding of their properties. They have also been considering what possible applications there might be.

MXene has already shown promise in water filtration, chemical sensing, and structural reinforcement. It has also shown potential in gas separation, electromagnetic shielding, and energy storage.

MXene vs. other new materials

The emergence of MXene has drawn comparisons with graphene and other two-dimensional devices. Scientists have also explored graphene as a material for printable antennas.

The Drexel scientists compared the spray-on antennas with several antennas made from graphene, silver ink, and other new materials. The MXene spray-on antennas were 300 times better than silver ink and 50 times better than graphene. Specifically, better regarding preserving the quality of radio wave transmission.

Babak Anasori said:

“The MXene antenna not only outperformed the macro and micro world of metal antennas, we went beyond the performance of available nanomaterial antennas, while keeping the antenna thickness very low.”

“The thinnest antenna was as thin as 62 nanometers – about one thousand times thinner than a sheet of paper – and it was almost transparent.”

“Unlike other nanomaterials fabrication methods, that requires additives, called binders, and extra steps of heating to sinter the nanoparticles together, we made antennas in a single step by airbrush spraying our water-based MXene ink.”

Babak Anasori, PhD, is a Research Assistant Professor at the A.J. Drexel Nanomaterials Institute.

Initially, the researchers tested the spray-on application of the antenna ink on cellulose paper and polyethylene terephthalate sheets. In other words, on a rough and smooth substrate.

They now plan to look at the best ways to apply it to many different surfaces, from glass to skin and yarn.

Prof. Anasori said:

“Further research on using materials from the MXene family in wireless communication may enable fully transparent electronics and greatly improved wearable devices that will support the active lifestyles we are living.”

Citation

“2D titanium carbide (MXene) for wireless communication,” Asia Sarycheva, Alessia Polemi, Yuqiao Liu, Kapil Dandekar, Babak Anasori, and Yury Gogotsi. Science Advances, 21 Sep 2018: Vol. 4, no. 9, eaau0920. DOI: 10.1126/sciadv.aau0920.