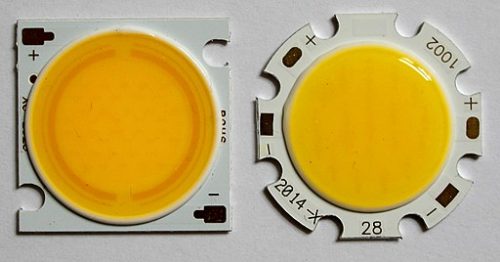

The full form of the abbreviation COB is ‘chip on board ‘. It is a combination of multiple LEDs that combine together to form a unit. A unit consists of maybe nine or more chips together in a set. This will eventually lead to more lighting. What is best is that this will not look like different or many separate lightings rather one single light. The energy consumption is less, but the brightness is more in these types of lights.

Where is this technology used?

One of the most common uses of cob led is in LED screens, both mini and micro. It gives high-resolution videos and gives the spectators an amazing visual experience. Other places where COB LEDs are used are:

- Mobile phones and flashes

- Lamps which are used for household purposes

- Street lights

- Lighting used in hallways and passages

- LED Strip

- Downlights

- Track lights

Why should you use COB LEDs?

- Simple Design: The design is simple as there is only one circuit with two power contact points that provides energy to all the chips. This, in turn, reduces the need for many components for a single Led chip.

- More Brightness / Lighting: There are multiple chips packed together in a particular area which results in more lighting. The brightness is more as compared to any standard LEDs as there are more sources of light in that limited area.

- Heat resistance: Fewer components accompanied by packaging changes in the standard structure of the chip reduce the amount of heat that is generated from every single LED chip. When paired to an external heatsink, the aluminium or ceramic substrate acts as a good medium for the transfer of heat, thereby reducing the operating temperature of an assembly line. One must carefully choose a heatsink that is able to dissipate the heat produced.

- Reduced rate of failure: As each LED chip does not need to be spot welded, there are fewer chances of failures. Each chip is directly mounted on the base surface, thereby reducing the chances of failure.

- Better lighting: The amount of light that is lost in traditional LED because of lenses is more as compared to COB LEDs. COB LEDs produces high lumens per watt, which means more light in fewer watts.

- Low cooling cost: There is a short thermal path with a large area for thermal dissipation and small resistance, which can effectively reduce the cooling cost.

- Greater angle for viewing: the angle is almost as close as 180 degrees which diffuse colour properly and gives a better lighting effect.

- Easy installation: The COB LED unit can be installed quickly and conveniently. This reduces the cost of installation that is generated from the manufacturer’s point of view.

- Easy to maintain: the surface of COB is both hard and smooth and can be easily cleaned. It is also resistant to wear and collision. Any dust particles collected can be cleaned with a duster cloth. It is also resistant to water, dust, moisture, static electricity, UV light, and oxidation. It is an all-weather product.

Some challenges to COB LEDs

- Who doesn’t love choices? But unfortunately, COB LEDs come in limited colours only, namely green, blue, white, red, and pink.

- There is no chance for repairs. If any one of the LEDs in the chip-on-board gets damaged because of any internal problem, the whole cob led must be changed with a new one.

- They are costlier than Surface Mounted Device LEDs.

- The cost of production of chip-on-board LEDs is higher than surface-mounted LEDs as this has more chances of failure. Additionally, the cost of maintenance is also high.

- The process needs highly skilled people, due to which the cost of production increases.

- When the size of the LED chip is decreased, its light efficiency also decreases.

Conclusion

All the above points explain the importance of chip-on-board LEDs. It is the latest technology in the market. As more and more people realize the advantages of COB LEDs, their application is increasing in various lighting devices. Since more LEDs can be packed into smaller spaces and more lighting is produced, it has become the first choice for application to lighting devices. So, the next time you go out to shop LEDs, do try this new technology.

Interesting Related Article: “8 Benefits of LED Lighting For The Aerospace Industry“