European researchers are preparing for climate-neutral airplanes powered by sustainably produced hydrogen.

In 2023, the European Union launched a project to support universities and industry in the creation of a hydrogen-powered medium-haul aircraft.

The term “medium-haul” in aviation typically refers to flights with a range between approximately 932 and 1,864 miles (1,500 and 3,000 kilometers). Examples of medium-haul flights are Dublin-to-Rome (1168.18 miles or 1,880 km) or New York-to-Chicago (939.33 miles or 1,511.71 km).

Current jet engines are optimized to run on kerosene. Future ones will need to be adapted to run on a more environmentally-friendly fuel.

Nicolas Noiray, a Professor in the Department of Mechanical and Process Engineering at ETH Zurich, Switzerland, said:

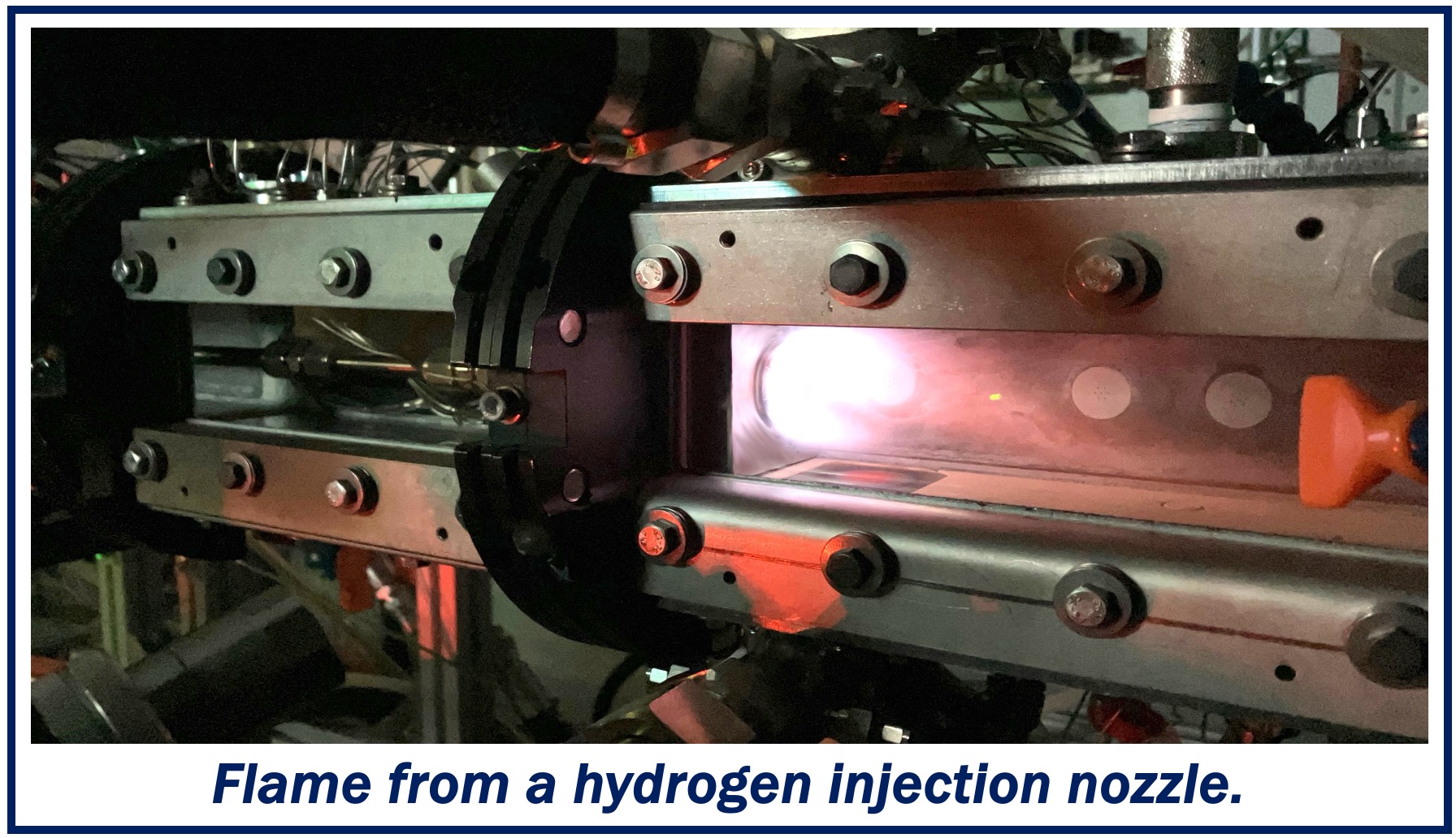

“Hydrogen burns much faster than kerosene, resulting in more compact flames.”

Noiray and colleagues have just created a jet engine that is powered by hydrogen. They wrote about their work in the peer-reviewed academic journal Combustion and Flame (citation below).

Minimizing Vibrations with Hydrogen Engines

One challenge engineers face is minimizing vibrations. In traditional jet engines, approximately twenty fuel injection nozzles are arranged around the annular combustion chamber of the engine. The turbulent combustion of the fuel within this chamber generates sound waves.

The waves reflect off the chamber walls and create a feedback effect on the flames. This coupling between the sound waves and flames can lead to vibrations that place a significant load on the engine’s combustion chamber.

Abel Faure-Beaulieu, a former postdoctoral researcher in Noiray’s group, said:

“These vibrations can fatigue the material, which in the worst case could lead to cracks and damage. This is why, when new engines are being developed, care is taken to ensure that these vibrations do not occur under operating conditions.”

Simulating conditions at cruising altitude

When kerosene engines were first designed, engineers had to get these vibrations under control. They managed to do this by optimizing the shape of the flames and the combustion chamber’s geometry and acoustics.

However, the type of fuel they use has a significant impact on the interactions between sound and flame.

This means that engineers and researchers must now ensure that these vibrations do not occur in the new hydrogen engine.

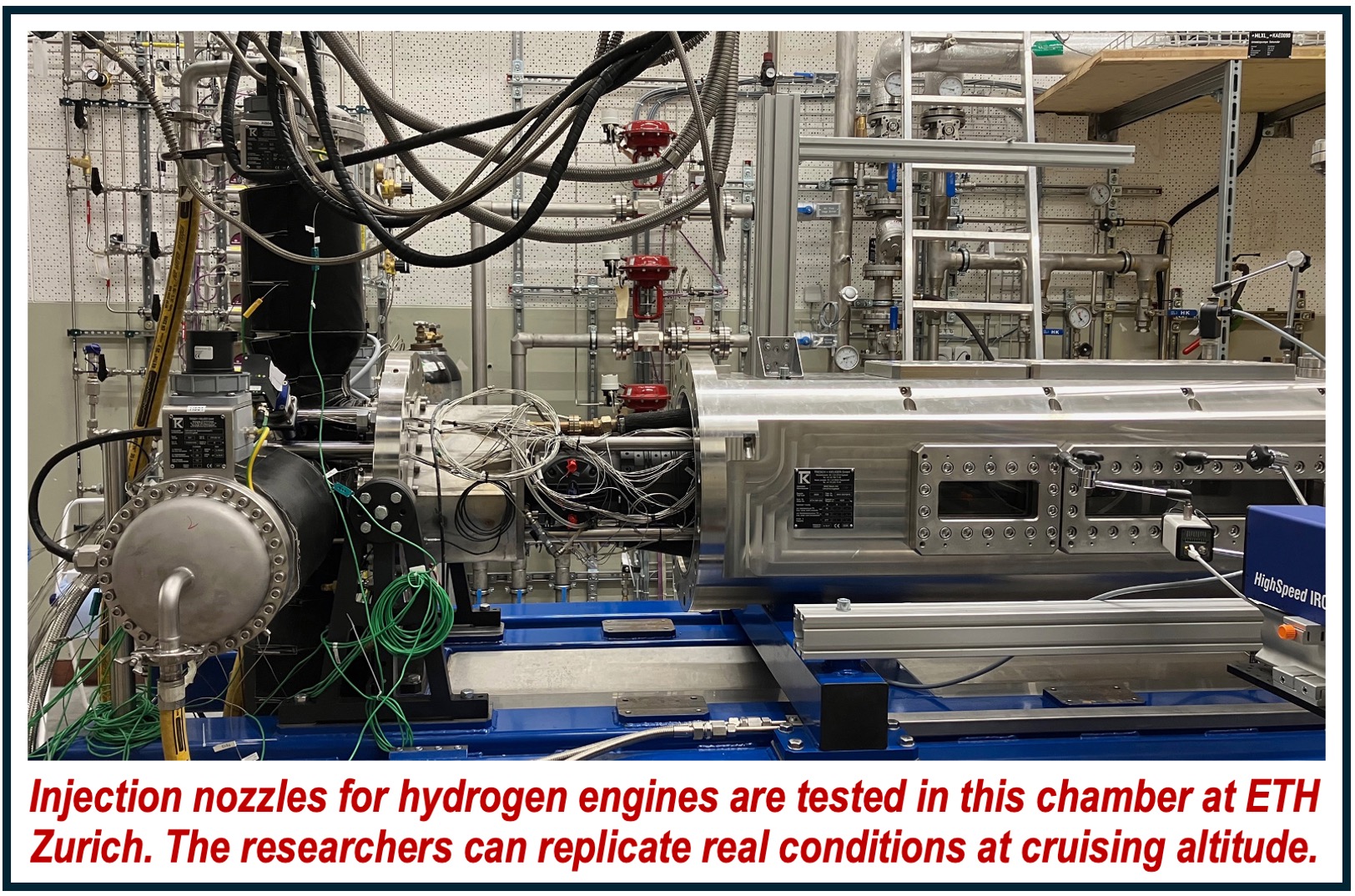

ETH Zurich has a sophisticated test and measurement facility that enables Noiray to analyze the acoustics of hydrogen flames and forecast potential vibrations. As part of the EU project HYDEA, in collaboration with GE Aerospace, he tests hydrogen injection nozzles manufactured by the company.

Noiray explains:

“Our facility allows us to replicate the temperature and pressure conditions of an engine at cruising altitude.”

The research team is also able to recreate the acoustics of several different types of combustion chambers, enabling a wide range of measurements.

Noiray added:

“Our study is the first of its kind to measure the acoustic behavior of hydrogen flames under real flight conditions.”

The researchers conducted experiments with a single nozzle and modeled the acoustic behavior of the collection of nozzles as it would be arranged in a future hydrogen-powered engine.

The researchers say that their study is helping GE Aerospace engineers optimize the injection nozzles, bringing us closer to a high-performance hydrogen engine.

Prototype a Few Years Away

The engine should be ready for preliminary tests on the ground in a few years. It could, one day, propel the first hydrogen-fueled airplane.

The greatest challenge in transitioning aviation to the hydrogen age is not the development of the engines or hydrogen tanks for the aircraft, the researchers explain.

“Humanity has flown to the moon; engineers will undoubtedly be able to develop hydrogen planes,” Noiray says.

However, for hydrogen to take off we need more than just planes. According to Noiray, another major challenge is to have the whole infrastructure for hydrogen aviation set up and ready. We also need to produce enough climate-neutral hydrogen and transport it to airports around the world.

Accomplishing this within a realistic timeframe demands a coordinated effort starting now.

Benefits of using hydrogen

Hydrogen, when produced from renewable energy sources like solar energy, wind power, or tidal energy, offers several advantages over traditional jet fuel. Here are three of them:

-

Zero Carbon Emissions

When we burn hydrogen, we only get water vapor as a byproduct. If all airplanes used hydrogen, greenhouse gas emissions from aviation would be significantly lower.

-

Less Air Pollution

Hydrogen combustion emits fewer pollutants, such as particulate matter and nitrogen oxides. These emissions contribute to air pollution and climate change.

-

Renewable Energy Integration

Using renewable energy to produce hydrogen helps create a more sustainable and eco-friendly energy supply.

While there are several challenges to overcome, such as hydrogen storage and distribution, the potential environmental benefits that hydrogen fuel offers make it a promising option for the future of aviation.

Citation

Faure-Beaulieu, A., Dharmaputra, B., Schuermans, B., Wang, G., Caruso, S., Zahn, M., & Noiray, N. (2024). Measuring acoustic transfer matrices of high-pressure hydrogen/air flames for aircraft propulsion. Combustion and Flame, 270, 113776. https://doi.org/10.1016/j.combustflame.2024.113776